As you search for an asset and maintenance management solution, you will encounter two primary types of software: computerized maintenance management system (CMMS) software and enterprise asset management (EAM) software. Because they share similar functionality, the differences between CMMS and EAM are not always clear; however, there are differences. This article examines CMMS vs. EAM software to clear up confusion between the two so that you can select the appropriate system for your organization.

CMMS Software vs. EAM Software

It’s no surprise that CMMS and EAM are often confused for one another. Some CMMS vendors market their product as EAM software, even if it is inaccurate to do so. That said, over time CMMS software packages have become more robust, further muddying the waters for buyers trying to distinguish between the two solutions.

While CMMS and EAM software are alike in some respects, they are in fact different in their functionality and application. First, let’s break down the basics of each system.

What is CMMS Software?

A computerized maintenance management system (CMMS) is a software program designed to help you manage maintenance activities and resources in order to keep assets in optimal condition. As its name describes, a CMMS focuses on maintenance. Core features of a CMMS include work order management and preventive maintenance scheduling, but many systems go above and beyond these basic capabilities. Our article What is a CMMS? provides a more in-depth explanation of computerized maintenance management system (CMMS) software.

What is EAM Software?

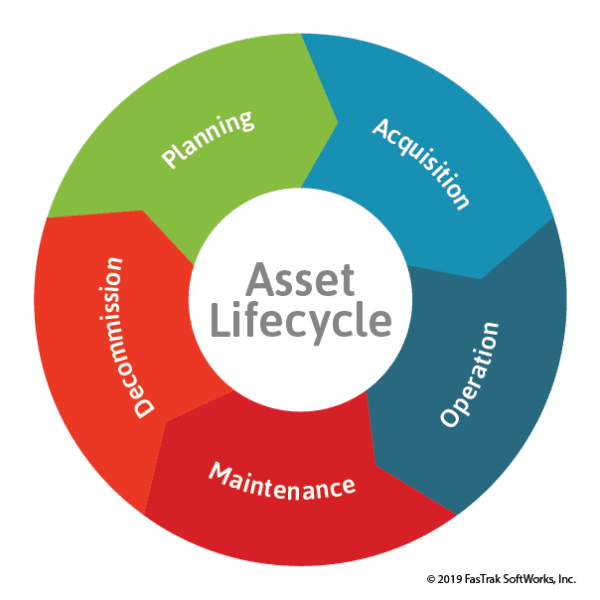

Enterprise asset management (EAM) software considers the entire asset lifecycle, from planning to decommission. It has a wide range of features used to track energy consumption, depreciation, MRO procurement, engineering, safety and compliance, and more. EAM software also includes some maintenance management functionality, though it is not a primary focus of the system.

Compared to CMMS which is primarily used by the maintenance department, an EAM may be used organization wide. For example, employees from accounting and finance, operations, and production are frequent users of an EAM, in addition to maintenance personnel.

CMMS and EAM: Two Sides of the Same Coin

CMMS and EAM software share similar goals and contain some of the same functionality. Where the two types of software really differ is their approach to asset management.

Scope of CMMS vs. EAM Software

EAM software takes a holistic approach to asset management, finding ways to maximize an asset’s value at every stage of the lifecycle: planning, acquisition, operation, maintenance, and decommission. Doing so requires contributions from multiple business functions such as accounting, production, and engineering, in addition to maintenance. EAM is most useful in asset-intensive organizations with a large number of assets (thousands to tens of thousands or more) spread across multiple locations.

CMMS, on the other hand, seeks to maximize asset performance during operation, after it has been purchased and installed. The more narrow focus of a CMMS makes it a powerful tool for managing maintenance, but it is not necessarily designed to do more. However, some CMMS solutions offer multisite support and other features that resemble the functionality of EAM.

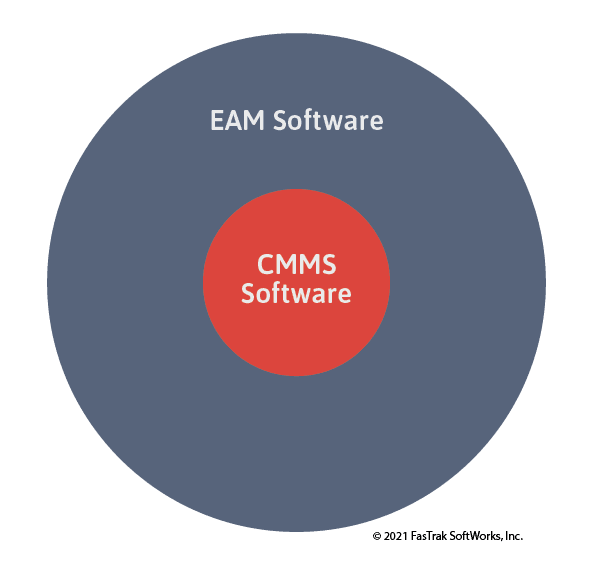

One way to think about the relationship between CMMS and EAM is by visualizing two concentric circles. Enterprise asset management is more comprehensive than maintenance management, and encompasses all stages of an asset’s lifecycle. Maintenance management, on the other hand, is focused on a single stage of the lifecycle – maintenance. Based on the graphic above, one could say that while all (or most) EAM solutions have the capability of a CMMS, not all CMMS solutions are as broad as EAM software.

Which Software is Best for My Business: CMMS or EAM?

The best way to determine which type of software is right for your business is to consider your organization’s asset management needs.

CMMS software is ideal for smaller organizations looking to improve asset uptime. It provides a powerful platform for helping organizations move from reactive maintenance to a more proactive mindset. Besides work order management and preventive maintenance, CMMS solutions often have MRO inventory management functionality. However, organizations implementing high-level maintenance strategies like reliability-centered maintenance (RCM) and failure modes and effects analysis (FMEA) may quickly outgrow a CMMS.

EAM software is a good choice for organizations that: 1) have a large portfolio of assets, 2) operate multiple sites, and 3) want to reduce the total cost of ownership (TCO) of their assets. It offers the advanced tracking and analytical tools required to manage assets at an enterprise level. Smaller organizations may find EAM software to be too overwhelming for their needs.

Improve Maintenance Operations with FTMaintenance

FTMaintenance is full-featured CMMS software that provides powerful tools for managing equipment and facility assets, work orders, MRO inventory, and preventive and corrective maintenance. It is designed to help organizations gain better control of maintenance operations through the documentation, management, organization, and analysis of maintenance activities. Schedule a demo to learn more about how FTMaintenance can improve your maintenance operations.