On-Time Work Order Performance is a common metric organizations use to evaluate the maintenance team’s efficiency and performance. While this metric may appear simple on the surface, it becomes more nuanced when tailored to specific goals. It is important to understand these subtleties, as ignoring them may lead to faulty conclusions or missed opportunities.

In this article, we explore two approaches to measuring On-Time Work Order Performance that underscore the importance of aligning your key performance indicators with your organization’s goals.

On-Time Work Order Performance Formulas

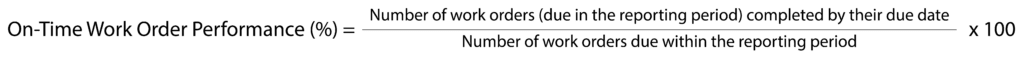

Formula #1: Measuring Completion of Work Orders Due within a Defined Period

The version of the On-Time Work Order Performance metric above measures performance within a defined period. It is commonly used in CMMS systems because it is a straightforward, “back-of-the-envelope” calculation that is easy to understand and interpret.

To calculate On-Time Work Order Performance, simply take the number of work orders due within a certain period that were completed by their due date divided by the number of work orders due within that same period.

Let’s look at an example with a reporting period of March 2024. Suppose 300 work orders had a due date in March 2024, and 260 of them were completed by their due date. Therefore:

On-Time Work Order Performance = 260 work orders due in March and completed by their due date / 300 work orders due in March = 260 / 300 = 0.86 * 100 = 86%

Like we said, the math is simple. Let’s take a closer look at what this metric is measuring. This calculation is focused on the completion of work that was due in this timeframe – March, in this example. It does not account for all work that was completed in March, such as work orders with a February due date completed late (in March) or with an April due date completed early (also in March).

While simple, this formula measures performance for March’s work orders only, and presents an imprecise picture of the maintenance team’s overall productivity. Measuring performance for all work completed requires a more complex, yet more precise formula – which brings us to our second formula.

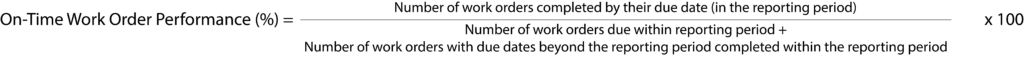

Formula #2: Measuring All On-Time Work Completed

As you can see, this On-Time Work Order Performance formula is a bit more complicated than the last. Don’t worry – we will break it down, step by step, so that you have a full understanding of how to calculate and interpret it.

Number of Work Orders Completed by Their Due Date in the Reporting Period

The first piece of data needed is the number of work orders completed by their due date in the reporting period. Unlike the previous formula, which only counted work orders both due and completed within the time frame, this formula accounts for work that is completed early. By “early”, we mean work that had a due date beyond the reporting period, but completed within the reporting period. In other words, if calculating this metric for a March time frame, work orders with an April due date that were completed in March would be counted.

Number of Work Orders Due within Reporting Period

This variable is the same as in formula 1. It is the number of work orders due within the reporting period. Continuing with our example, it is how many work orders were due in March (i.e., had a March due date).

Number of Work Orders Due within Reporting Period, but Completed Before the Reporting Period

When circumstances allow for it, maintenance teams perform work orders early. It would not be fair for work orders completed early – in a previous reporting period – to be included in the count of work orders due in this reporting period. Using our example, it would not be right for a work order that was due in March, but completed in February, to be factored in to March’s report.

If not removed, this “double counting” will result in inaccurate results. Therefore, such work orders are removed in the calculation for this period, but are accounted for in a previous period’s reporting.

Number of Work Orders with Due Dates After the Reporting Period Completed within the Reporting Period

While the previous component of the formula ensures that credit is not being given for work completed before the reporting period, we do want to include any work completed this period that has a due date that is after the reporting period. In other words, the maintenance team should be recognized for completing work early.

Putting it All Together

Let’s walk through an example, using the same information from earlier. In March 2024, there were 300 work orders with a March due date, and 260 of those were completed by their due date.

On-Time Work Order Performance = 260 work orders due in March and completed by their due date / 300 work orders due in March – X work orders due in March, but completed before March + X work orders due after March, but completed in March

Now suppose that 5 work orders with March due dates were completed in January, and 15 were completed in February. That’s a total of 20 March work orders completed before March.

On-Time Work Order Performance = 265 work orders due in March and completed by their due date / 300 work orders due in March – 20 work orders due in March, but completed before March + X work orders due after March, but completed in March

In addition, 5 work orders that were due in April were completed in March. Therefore:

On-Time Work Order Performance = 265 work orders due in March and completed by their due date (i.e., 260 due and completed in March, 5 due in April but completed in March) / 300 work orders due in March – 20 work orders due in March, but completed before March + 5 work orders due after March, but completed in March

On-Time Work Order Performance = 265 / (300 – 20 + 5) = 265 / 285 = 93%

As we mentioned before, this version of the formula measures the maintenance team’s overall performance, not just their performance on work orders due in a specific timeframe. This example proves that the maintenance team was being productive, even if they did not complete all work orders due in March on time. However, a handful of April’s work orders have been completed early, lightening the work load in the future.

Which Formula Should I Use?

Selecting the most appropriate On-Time Work Order Performance formula comes down to your goals and what you are trying to measure. Each metric is correct in its own right. If the first formula provides sufficient enough information in relation to your goals, it may be used over the second, more complex formula that is technically more precise, but doesn’t directly contribute to decision-making.

Track Work Order KPIs with FTMaintenance Select

There are seemingly endless ways to track and measure maintenance team performance. However, it is critical that your key performance indicators (KPIs) are rooted in your organization’s goals. FTMaintenance Select helps you monitor your performance by allowing you to document, manage, track, and report on all aspects of your maintenance operation. Request a demo today to learn more.