Assets that fail unexpectedly result in costly downtime, lost productivity, and safety risks. While preventive maintenance can reduce the likelihood of failures, it doesn’t account for an asset’s actual condition and often leads to over-maintenance.

Predictive maintenance (PdM) helps organizations anticipate equipment failures by leveraging real-time data, allowing them to perform maintenance only when truly necessary. In this article, we explore how predictive maintenance enables a more proactive, data-driven approach to failure prevention.

What is Predictive Maintenance?

Predictive maintenance (PdM) is a proactive maintenance technique that uses real-time asset data (collected through sensors), historical performance data, and advanced analytics to forecast when an asset failure will occur.

Using data collected by condition-monitoring devices during normal operation, predictive maintenance software uses advanced formulas (called algorithms) to compare real-time data against known measurements and accurately predict asset failure. This data is often integrated and managed within a computerized maintenance management system (CMMS), which helps track asset data and schedule work orders based on these predictions.

Advanced PdM techniques may incorporate cutting-edge technologies such as machine learning and artificial intelligence (AI). The result of PdM is that maintenance work can be scheduled and performed before an asset is expected to fail, thereby helping minimize downtime.

Preventive Maintenance vs. Predictive Maintenance

Preventive maintenance (PM) and predictive maintenance share a common goal – to stop asset failures before they happen. However, they differ in their approach.

In a typical PM program, maintenance activities are commonly scheduled according to strict time-based or usage-based intervals, manufacturer recommendations, or as a result of inspections. While useful, these methods only detect obvious problems based on one’s sense of sight, sound, touch, and smell.

Predictive maintenance relies on data gathered through condition-monitoring sensors that can detect internal wear that cannot be directly observed, is too dangerous for humans to inspect, or would otherwise require equipment to be shut down and opened up. Maintenance events are then scheduled based on an asset’s real condition and performance, and performed only when needed.

Condition-based Maintenance vs. Predictive Maintenance

Condition-based maintenance (CbM) and predictive maintenance are closely related strategies, but differ in how and when they trigger maintenance tasks.

CbM involves monitoring equipment in real time or at set intervals to measure whether equipment performance exceeds predefined thresholds. For example, a work order may be triggered if a vibration reading goes beyond an acceptable limit. While this approach prevents some failures, it is still largely reactive – maintenance is only performed when warning signs are already present.

Predictive maintenance takes condition monitoring a step further by using advanced analytics and machine learning to detect subtle patterns in sensor data that indicate future failure. This proactive approach gives maintenance teams more time to act or schedule maintenance well-before failure occurs.

How Predictive Maintenance Works

Predictive maintenance involves three main components:

- Capturing sensor data

- Communicating data

- Making predictions via data analysis.

Let’s use an analogy to explain: think of the weather forecast provided by your local TV news station. To provide an accurate weather forecast, meteorologists collect and analyze weather data obtained from multiple sources, such as Doppler Radars, satellites, and surface-level weather stations. These devices measure conditions such as air temperature, wind speed, and barometric pressure, and send the data to a database.

With the assistance of computer-based modeling and analytics tools, meteorologists are able to turn the stored data into a weather forecast presented to viewers. Based on the forecast, viewers can prepare for the days ahead, including how to dress, what road conditions are expected, and how travel times may be affected. Predictive maintenance works in a similar way.

Although you cannot control all events, with an accurate prediction you can often prevent asset failure. Just as meteorologists rely on specialized tools to measure weather patterns, predictive maintenance depends on multiple technologies to monitor asset health.

Capturing Sensor Data

Predictive maintenance utilizes sensors and nondestructive testing to evaluate an asset’s performance and condition. Condition-monitoring sensors can perform spot checks at regular intervals or continuously monitor assets while they are in normal operation. Common condition-monitoring technologies include:

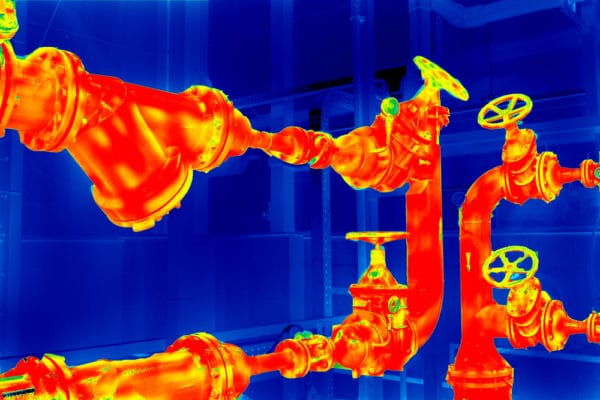

- Infrared thermography: Detects temperature using infrared imaging.

- Acoustic monitoring: “Listens” for sonic and ultrasonic frequencies.

- Current analysis: Measures voltage and electrical current.

- Corona detection: Identifies electrical discharge.

- Vibration analysis: Monitors displacement, velocity, or acceleration to identify vibration patterns.

- Oil analysis: Checks lubrication of machinery and assesses oil condition.

Communicating Data

Once sensors have captured equipment condition and performance data, it must be stored and analyzed. One advanced communication technology is called the Internet of Things (IoT), where equipment sensors send and share information via a wired or wireless internet connection. Data is sent to, and stored in, a database where it awaits analysis.

Making Predictions

The defining function of predictive maintenance is the ability to forecast when an asset will fail. This capability is what sets PdM apart from condition-based maintenance. Data is collected and analyzed using algorithms to compare an asset’s current performance against its expected performance, determine the level of deterioration, and estimate when maintenance will be needed.

More advanced PdM programs apply machine learning to historical failure patterns, using sophisticated models to more accurately predict remaining useful life (RUL). These models improve over time as they learn from additional data, making predictions increasingly more accurate and reliable.

However, the accuracy of predictive maintenance depends heavily on the quality of the data collected. If sensors are improperly calibrated, data is incomplete, or CMMS records are outdated, the predictions generated by PdM algorithms may be unreliable. Therefore, in addition to their regular maintenance work, maintenance teams must regularly verify that sensors are functioning properly.

CMMS software supports predictive maintenance by providing historical equipment data for use in predictive algorithms. It also contributes to maintenance planning by generating, scheduling and tracking work orders based on predictive analysis.

Advantages of Predictive Maintenance

The U.S. Department of Energy’s Operations and Maintenance Best Practices Guide reports that predictive maintenance can reduce maintenance costs by up to 30%, eliminate breakdowns by up to 70%, and increase equipment uptime by as much as 35%. In addition, predictive maintenance offers these additional benefits:

- Improved Ease of Maintenance Scheduling: Since the need for service is known well-before work is actually required, activities can be scheduled when equipment is available for maintenance.

- Increased Asset Uptime: Assets can remain in operation until maintenance is truly warranted. Other strategies may cause excessive downtime due to over-maintaining, under-maintaining, or unexpected breakdowns. By relying on actual equipment condition, PdM minimizes unnecessary downtime.

- Combined Benefits of Other Maintenance Techniques: PdM combines the proactive nature of preventive maintenance with the real-time monitoring of CbM to deliver optimal timing and resource use.

- Lower MRO Inventory Costs: Predictive maintenance helps maintenance teams better forecast inventory demand, reducing last-minute purchases, expedited shipping costs, and excess MRO inventory.

- Improved Safety: PdM helps identify and address potential failures before they become more severe, helping to reduce the risk of equipment-related damage and accidents.

Disadvantages of Predictive Maintenance

Even with all its benefits, be aware of some of the potential drawbacks of predictive maintenance.

- Large Upfront Cost: A predictive maintenance program requires a large investment in condition monitoring hardware, advanced analytical software, employee training, and man-hours to purchase and install. These costs can be a barrier to smaller organizations or those with limited budgets.

- Required Expertise: PdM requires staff with specialized knowledge in sensor technology, data interpretation, and software tools. These technical skills may not be readily available in every organization.

- Not Cost-Effective for All Assets: PdM is best applied to mission critical, high-value assets. Simpler maintenance strategies may offer a better return on investment for low cost, non-critical equipment.

When to Use Predictive Maintenance

Deciding whether to use predictive maintenance depends largely on its return on investment (ROI). That is, whether the cost savings from avoiding unplanned downtime and extending asset life will outweigh the costs of implementation. Organizations should also consider an asset’s criticality and repair vs. replacement cost. PdM is most valuable for high-value, production-critical assets whose failure significantly disrupts operations.

Industries with remote or mobile assets – such as oil and gas, utilities, and fleet maintenance – also benefit from predictive maintenance, as it reduces the need for frequent site visits and allows maintenance to be scheduled only when necessary.

Additionally, compliance with industry standards or contractual obligations may require adopting predictive maintenance practices. For example, international standards such as ISO 17359 provide best practices for condition monitoring and diagnostics, which some organizations adopt to meet customer expectations, regulatory oversight, or quality certifications.

However, predictive maintenance is not the right fit for all assets. For example, using sensors to monitor a facility’s roof for leaks would require numerous sensors, without a guarantee they’d be placed in areas where issues actually occur. In such cases, preventive maintenance tasks, such as regular inspections, are more practical and cost-effective. Similarly, for assets that are inexpensive or easily replaced, setting up a PdM program may outweigh any potential savings.

It is important to understand that implementing a predictive maintenance program is not immediate. Organizations may spend several months collecting baseline performance data, fine-tuning predictive algorithms, and integrating their CMMS. While the long-term payoff can be substantial, it requires careful planning, consistent data input, and ongoing evaluation to achieve ROI.

Anticipate Equipment Failures with FTMaintenance Select

Predictive maintenance is an advanced maintenance strategy that helps you avoid unnecessary downtime and maintenance intervention. While implementing PdM is a large undertaking, it is more manageable with the right tools in place.

FTMaintenance Select is a comprehensive CMMS solution that helps you document, manage, and track maintenance activities from a single platform, regardless of which maintenance strategies you use. Our work order software automates work order creation, notification, distribution, and completion to help you stay ahead of issues and keep operations running smoothly. Mobile CMMS extends your CMMS to technicians in the field, allowing real-time work order management while on the go. Request a demo today to see how FTMaintenance Select empowers you to become more proactive about failure prevention.