In industrial environments, critical asset information is often scattered across multiple locations, stored in different systems, and saved in various formats. When maintenance teams lack access to accurate equipment information, it can delay repairs, lead to incorrect part orders, and increase costly downtime.

An equipment bill of materials (EBOM) plays a key role in supporting effective asset management and maintenance. In this article, we provide an overview of equipment bills of materials and how they impact maintenance operations.

What is an Equipment Bill of Materials (EBOM)?

An equipment bill of materials (EBOM) is a list of all components, subassemblies, and materials used to manufacture or assemble a piece of equipment. It reflects the actual configuration of a physical, installed asset, and serves as the technical reference throughout the equipment’s lifecycle.

EBOMs are typically created by the original equipment manufacturer (OEM) or engineering team, and delivered to customers when the equipment is installed. Once installed, it is used by the organization’s engineering, reliability, and asset management teams to support asset lifecycle tracking, root cause analysis (RCA), maintenance management, and MRO (maintenance, repair, and operations) inventory management.

EBOM vs. Maintenance Bill of Materials

Many sources blur the line between an equipment bill of materials and a maintenance bill of materials, though they have different purposes and stakeholders.

An EBOM details out the full design of the equipment, while a maintenance-focused BOM is scoped to day-to-day maintenance activities. Though based on an EBOM, it includes only items that may need to be repaired or replaced, essentially making it the equipment’s spare parts list.

This version may also contain practical, relevant details such as quantity used, storage location, equivalent alternatives, and reorder information. With this narrowed focus, maintenance teams can more easily track, stock, and manage the parts necessary to keep equipment up and running.

How an EBOM Supports Maintenance Operations

An equipment bill of materials plays a vital role in day-to-day maintenance operations. Many maintenance stakeholders either directly or indirectly use the EBOM to inform asset management, inventory decisions, maintenance planning, and troubleshooting. The table below highlights how various stakeholders use the EBOM, or information derived from it, to support maintenance activities.

| Stakeholder | EBOM Helps Stakeholder… |

| Maintenance manager |

|

| Maintenance planner |

|

| Maintenance technician |

|

| Inventory management staff |

|

| Purchasers |

|

| Operations and reliability engineers |

|

EBOM Structure

Depending on the level of detail required, an equipment bill of materials may take many forms. Typically, EBOMs follow either a single-level or indented multi-level structure.

Single-level EBOM

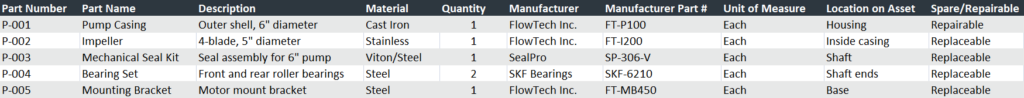

A single-level EBOM simply lists all the components, subassemblies, and spare parts used in the equipment, typically showing each part only once along with the total quantity included in the design. It provides a flat, straightforward list without showing hierarchical relationships.

Multi-level EBOM

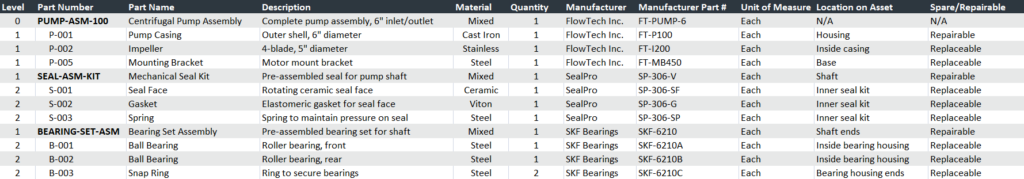

A multi-level EBOM illustrates the hierarchical structure of equipment by showing assemblies, subassemblies, and individual components in a parent-child relationship. This relationship is often visualized through indentation or levels, showing which parts “belong to” or are organized under others. In this format, parts may appear multiple times if they are used under different parent structures.

EBOM Maintenance

Equipment bills of materials are not “set and forget.” There are a number of events that require EBOMs to be updated:

- Decommissioning and retirement: When assets are taken out of use and/or dismantled, an accurate EBOM identifies which parts are unique and can be sold or scrapped. Parts used elsewhere can be put back into inventory.

- Design changes: Assets that have been redesigned, refurbished, or otherwise modified may use new and different components. These items should be included in the EBOM, along with any alternatives.

- Part substitution: Due to availability issues, there exists a need to identify alternative parts that are viable substitutes. The EBOM or part record in the CMMS can show this relationship.

- Part standardization: To streamline inventory procurement and purchasing, parts may be standardized across similar assets or across plants. Amend the EBOM to show these changes, including effective start and end dates of new parts.

- EBOM review: EBOMs may go through informal or formal review throughout their lifetime. Informal reviews may happen as EBOMs are being used by those with specific knowledge about the asset. More formal reviews may be performed periodically by key maintenance stakeholders.

A well-maintained EBOM tracks changes to a piece of equipment’s design throughout its lifetime, helping maintenance teams stay informed about new inventory needs, avoid using obsolete parts, and perform repairs more accurately and efficiently.

Maintenance teams, while not directly responsible for managing the EBOMs, provide insights from hands-on experience that help keep the EBOM accurate and relevant. They help keep EBOMs up-to-date by providing feedback on part performance, substitutions, and conditions observed during maintenance activities. This communication helps support continuous improvement in asset management.

EBOMs and CMMS Software

Equipment bills of materials contain detailed technical information about assets and their components. Maintenance teams greatly benefit from using EBOM data within their computerized maintenance management system (CMMS) software. Through a CMMS, maintenance teams can harness EBOM data to:

- Associate spare parts to specific assets, ensuring proper part selection.

- Create maintenance BOMs that track repairable and replaceable parts and components.

- Support better inventory management by linking parts with location and vendor information.

- Improve repair efficiency by providing technicians with reference documentation to help them visualize equipment structure and component relationships.

- Analyze part usage and failure trends to improve preventive maintenance planning, procurement, and purchasing activity.

- Enhance inventory accuracy and reordering by identifying obsolete parts, suitable alternatives, and economic order quantities.

By leveraging EBOM information in a CMMS, maintenance teams can make more informed maintenance decisions, reduce unnecessary downtime, and better manage MRO inventory throughout the asset lifecycle.

Leverage Your Asset Data with FTMaintenance Select

EBOMs provide maintenance teams with a wealth of technical data for planning, managing, and executing maintenance activities. FTMaintenance Select CMMS allows you to use EBOM information alongside work orders, preventive maintenance tasks, inventory data, and more within one centralized system. Bringing this information together helps your team make informed decisions, improve efficiency, and strengthen your asset management practices. Request a demo of FTMaintenance Select today to see how you can make the most of your equipment data.