Maintenance teams are commonly judged on how quickly they respond to asset failures. Mean Time to Repair (MTTR) is an important asset management metric used to help maintenance teams improve recovery times. This blog post shows you how to you calculate MTTR and how you can use it to improve your maintenance process.

What is Mean Time to Repair?

Defining mean time to repair (MTTR) is the first step in knowing how to use it. Mean Time to Repair is a maintenance metric that measures the average time required to repair an asset, from the moment an incident occurs until it is returned to service. It refers to the amount of wrench time that it takes to fix a problem. MTTR also demonstrates how quickly an organization responds when an unexpected breakdown occurs. This metric can bring visibility to problems with the maintenance process as it relates to making repairs.

The Benefits and Importance of Mean Time to Repair

There are several reasons that determining Mean Time to Repair is important, as well as benefits of doing so.

Discover Areas that Impact Downtime

Over time, comparing MTTR values helps maintenance teams assess whether there are issues with the asset, maintenance tasks, parts, staffing, scheduling, and/or employees. By making improvements in these areas, downtime can then be reduced. Responding to and resolving issues with assets quickly leads to more efficient production, which helps to retain customers and gain new ones.

Helps Evaluate Asset Performance

Mean Time to Repair provides a benchmark for maintenance managers to evaluate asset performance. It can also be used to identify assets that are candidates for replacement. Reports that display MTTR and related information can show how an asset is performing compared to similar assets. If one is performing significantly worse than others, the maintenance team can show there is cause for replacement.

Identifies Asset Outliers

One of the most important benefits is that Mean Time to Repair identifies asset repair outliers, assets that are significantly underperforming and the MTTR for them is high. Keep in mind that any number near the average of MTTR is not very helpful. It may be easier to determine outliers when more assets are being compared. If a few machines out of each similar group have a high MTTR, there is likely an underlying reason for it.

If an organization has many of the same kinds of assets, all assets of that type can be compared to see which of them have a high MTTR. Location and use of the machines matter as well, so the maintenance team needs to conduct a thorough analysis to find out why each of these machines’ MTTR is different.

Some questions to ask include, do these machines get misused by inexperienced technicians? Are some machines running beyond their rated capacity? It serves as a starting point to ask other subsequent questions, dig into the history of each asset, and examine what the causes of each asset failure were. If trying other ways to lower MTTR were unsuccessful, maintenance departments can question whether or not the assets need to be replaced.

Helps Shape Future Asset Buying Decisions

The results of calculating MTTR helps shape future asset buying decisions. They may get feedback from technicians as well since they are the ones doing the maintenance work. It’s worthwhile to ask if it is a make and model issue. If so, they can choose not to buy that same machine again. When an asset is brand new, it is will have an MTTR outlier, but it will usually be low, not high, so that number is not especially useful. But over the course of the asset’s lifecycle, looking for trends from a make and model perspective will help to identify outliers on the high end.

Who Uses Mean Time to Repair Information?

The information gathered from calculating mean time to repair is valuable to many people in an organization. It is especially relevant for maintenance managers, maintenance technicians, and production supervisors.

Maintenance Managers

Maintenance managers use MTTR to examine the maintenance jobs on certain machines that are taking the longest to complete and if there are ways to shorten the timeframe of these jobs. This can include a variety of assets and wrench times, but the key is finding outliers. If it’s determined that the MTTR is longer than desirable because of assets that are in poor condition, they may use that information to show upper management that the asset should be replaced.

Maintenance Technicians

Maintenance technicians may use MTTR to (informally) evaluate their own performance. It will help them reflect on what to improve that is in their control and what is out of their control. It allows them to see patterns in repairs that take longer or shorter periods of time. In some cases, it may help them to present a case for hiring more technicians. As a team, maintenance technicians can use MTTR information to set maintenance goals.

Production Supervisor

While the production manager or supervisor is not directly involved in the factors MTTR covers, they may be impacted by its results. If they are aware of the current state of MTTR on multiple types of repairs on specific assets, it can help them to understand that while there is an average downtime number on each type of machine, downtime overall will vary greatly depending on which asset is down, how major the repair is, and what it will take to fix the problem.

How to Calculate Mean Time to Repair

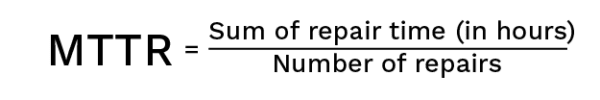

The Mean Time to Repair formula is shown below. Take the sum of all repair time (for similar repairs on an asset or group of assets) in hours and divide by the number of repairs that occurred within the specified time period.

It’s important to note that repair time can be defined as the time from the report of the problem to repair completion, or from the start of the actual repair work to completion. Most of the time, the latent period between when a problem occurs and when it is discovered is also included. Organizations will use one method or the other based on their needs.

The number of repairs is the total number of similar repairs done on the asset that MTTR is being calculated on within the specified time period. This formula gives the average time it takes to complete the repair process.

It’s worth noting that the MTTR calculation assumes that the tasks are performed sequentially (that is, in a standardized way and in the same order every time) and by appropriately trained personnel. Finding an ideal Mean Time to Repair heavily depends on the type of asset and the time required for each repair, which may vary greatly. Desired timeframes for repairs to be completed must be adjusted for the asset’s complexity and age.

If you are just starting to calculate MTTR and don’t have multiple years worth of data to look back on, you can come up with a number by calculating MTTR for a group of similar assets and apply that number to a specific machine in that group. It may take two or three years to get a true benchmark, whereas initially, only educated guesses can be made. Getting a good number for each repair type on each particular asset or group of similar assets is the goal.

How to Interpret Mean Time to Repair

In order to benefit from the results of calculating mean time to repair, maintenance teams need to know how to interpret them. MTTR can serve as a benchmark for future comparison. Remember that the number will rise and fall over time based on the types of repairs that were done during the time period calculated. The number should be determined for each type of repair in an asset class or individual asset as they will be different. There is no one ideal MTTR number because it depends on the type of asset and type of repair.

Another thing to remember is that initial calculations are a benchmark. MTTR values in subsequent calculations may be higher or lower. A lower number may reflect that an asset is new, since less severe problems occur with newer assets. A lower MTTR number might also mean frequent, short repairs are being made, so it’s not necessarily an indicator of how well repairs are being performed.

If MTTR numbers are higher, that could mean more major repairs were completed during the last calculation period, or it could indicate other issues. It’s important to look into what might be causing an increase in those numbers to determine if those factors can be changed or not.

Calculating Mean Time to Repair should be done at longer intervals rather than shorter ones. For example, if MTTR was calculated for a year’s worth of repairs the first time, the maintenance team should wait at least another full year before calculating MTTR again. However, after the first two years, a smaller timeframe may be appropriate to use to get quicker feedback. Comparing MTTR numbers that are too close together will not give an accurate mean time, or average number when establishing a baseline, but after that point, a long time frame is not as crucial.

An MTTR report can show how an asset is performing relative to similar assets and help to build a case for asset replacement or reflect on maintenance efforts for that asset. Many underlying issues can impact MTTR, so it needs to be determined whether changes are needed to staffing, scheduling, or inventory management.

Ways to Improve Mean Time to Repair

The MTTR metric may also help to improve maintenance scheduling, which in turn will improve MTTR values. Maintenance managers may change the frequency of some preventive maintenance, allow more or less time to complete certain jobs, or make adjustments to which technicians complete which jobs. Other ways to improve Mean Time to Repair include:

- Provide more in-depth training on asset function and repair techniques for new employees or as a refresher for existing employees.

- Implement predictive maintenance sensors to alert maintenance departments of problems before they become emergencies, which will result in faster, easier maintenance jobs.

- Continually update repair procedures and instructions to ensure they are performed in a standardized way.

What are the Limitations of Mean Time to Repair?

As with all maintenance metrics, there are limitations to MTTR. It doesn’t tell you where in the process an error or failure occurred. If MTTR is calculated over too short of a time period, the results will not be accurate. For some assets and types of failure, it takes several months or a year to gather enough data and determine an accurate number. For others assets and failure types, there may be enough data to calculate MTTR after a much shorter time frame.

In many cases, an increase in MTTR can reveal issues and a decrease can indicate improvements. However, it depends on the types of repairs being made. Major repairs take more time and increase MTTR while quick repairs can lower MTTR. Only repairs that are comparable to each other (apples to apples) can be included in the same MTTR calculation. Therefore, multiple MTTR numbers can be calculated for different types of repairs for the same asset. Either way, keeping track of MTTR over time helps maintenance personnel know how they’re performing.

Steps Included in Calculating Repair Time

Now that we’ve covered what Mean Time to Repair is, why it’s important, who uses it, and how to interpret it, next is to learn what tasks are included in the repair time calculation.

Diagnosing the Issue

Once the technician has been notified of the problem, the timeframe for calculating MTTR begins. The technician will come over to the machine and attempt to determine the issue. They may do an inspection, speak to the machine operator to learn more about the problem, and perform diagnostics.

Fixing the Issue

After the cause of the problem has been found, it’s time to fix the issue. Depending on what the repair is, this may be the longest part of the process. The machine is has already broken down, so production downtime has already been occurring. However, the technician will have to shut down the machine fully to begin the maintenance work. The time it takes to actually do the repair is measured closely. Any form of a lockout tagout procedure would also be included here.

Reassembling and Calibrating the Asset

After the machine is repaired, if needed, the machine is reassembled, aligned, and calibrated. If the maintenance work requires any disassembly of the machine, the parts need to be replaced.

Setting Up, Testing, and Starting the Asset Back Up

Lastly, repair time includes setting up the asset for production, testing its operation to ensure the repair fixed the problem, and starting the machine again. When the machine is fully up and running again, the period of Mean Time to Repair ends.

Calculate MTTR with FTMaintenance Select

Computerized maintenance management system (CMMS) software helps maintenance teams easily calculate Mean Time to Repair because all work order information including labor time records and individual repair records are recorded. This creates maintenance history, which stores and displays information about how long repairs took. It also holds data on how many and what type of repairs were done on each asset, what solved each maintenance problem, and information on the condition of each asset.

CMMS software also allows maintenance managers to make adjustments in the maintenance schedule to accommodate unexpected corrective maintenance work. The maintenance reports available in CMMS software help maintenance teams to calculate MTTR accurately.

FTMaintenance Select is a complete maintenance management software solution that can be used to track asset maintenance and repair time, including MTTR, build a maintenance history, track labor hours, and run asset reports. Request a demo today to learn more.