Work order management is a core function of maintenance management. A successful work order management process depends on how efficiently work orders progress through each stage of their lifecycle. Maintenance professionals use one of many work order management systems today, each with their own benefits and drawbacks.

This article provides an overview of the pros and cons of several common work order management systems in order to help you make the best decision for your organization.

No Work Order Management System

As surprising as it sounds, some organizations do not have a formal work order management system in place. This is typical of small organizations that operate in a completely reactive mode. Depending on the makeup of the maintenance team, veteran technicians determine what maintenance is needed based on their practical knowledge, experience, or “gut feeling.” Employees rely on their memory to know when maintenance is due.

| Pros | Cons |

|

|

Having no work order management system has no benefits other than cost. Unless maintenance staff has superb memory skills, having any type of organized system is better than having none at all. Without a work order management system, maintenance operations are thrown into chaos. Not only does no one know what work needs to be done and when, it is difficult to hold people accountable. Because of these factors, maintenance costs are high and no useful information is documented to help improve operations.

Paper Work Order Management System

Though using a paper-based work order management system seems outdated, it still thrives in today’s industrial environments. Paper work order management includes communication about maintenance work using non-computerized methods such as paper and pen, sticky notes, bulletin boards, and maintenance tags.

| Pros | Cons |

|

|

Paper-based work order management has existed seemingly as long as pen and paper has been used. Before computers, many businesses were run on paper-based systems. Their ease of use and familiarity are a large reason why so many organizations still use them today. In fact, operations in many organizations largely rely on printed documentation generated by computerized systems, such as work orders or invoices.

The primary advantage of paper work order management systems is that paper work orders are very portable. Technicians can fold paper work orders, tuck them into a pocket, put them in a folder, or attach them to a clipboard. Paper work orders can also be taken into harsh environments or areas with no internet connection, places where electronic devices may get damaged or become useless. It is also easier for technicians to grip a writing implement with gloves on than to type on a mobile device.

Due to its simplicity, paper-based work order management systems are very limited. Paper work orders are easily misfield, lost, or damaged. It can also be time-consuming to locate, retrieve, and organize them, leading to slower response times. Even if there are only minutes of time wasted, lost maintenance time adds up over time.

In terms of communicating maintenance information, paper work orders are prone to errors. Poor penmanship, misspellings, and misnumberings cause inaccuracies that indirectly impact other aspects of maintenance operations like accurate inventory tracking.

Finally, filing paper work orders requires storage space, which quickly runs out when hundreds of work orders are being processed regularly.

Email Work Order Management System

Another common method of managing work orders is to use email software. Organizations most commonly use Microsoft Outlook, as it comes preinstalled with a Windows operating system. Google’s Gmail is another popular option.

| Pros | Cons |

|

|

Like paper, email is familiar to everyone, whether used in their business or personal life. Email-based work order management digitizes work orders, making them easier and faster to distribute to employees. Maintenance managers may also attach computer files to emails to provide extra context to work orders. Technicians that desire a hard copy version of a work order have the ability to print them, attachments included.

A big advantage of email systems over others discussed so far is built-in scheduling capability. Organizations use calendar appointments to assign and schedule work orders at a specific date and time. Automatic notifications remind technicians of upcoming appointments.

Email-based work order management is not without its limitations. For one, emails require manual data entry in order to create and update work orders. One person is responsible for generating work orders from scratch, by copying and pasting from previous emails, or through managing templates in the form of email drafts.

Email communication presents additional difficulties. Emails sent to a single person cannot be seen by others; emails sent to groups provide more transparency but can lead to multiple responses for the same job and muddied conversations.

Finally, email software does not provide transparency between users. Technicians do not have access to an asset’s service history unless they have previously performed the work. Even so, workers do not have access to work that others have performed.

Recommended Reading: 10 Reasons to Use CMMS over Email

Spreadsheet Work Order Management System

The next level of functionality is the use of spreadsheet software as a work order management system. Spreadsheets are still used by many maintenance departments today. Microsoft Excel is the most commonly used spreadsheet software, as it is part of the Windows operating system on which most businesses run.

| Pros | Cons |

|

|

Spreadsheets are a popular way to manage work orders due to their ability to organize information through the use of tabs, columns, and rows. Files contain defined spaces to hold specific information, making it easy for users to know exactly where to find or enter information about maintenance activities. Formatting options like text styles and background colors can draw attention to important information.

Savvy users can use formulas, data validation, and other data management features to provide some level of automation. For example, a field can be set up to automatically calculate labor cost by multiplying labor hours by an employee’s hourly rate. Spreadsheet software also generates basic charts, graphs, and reports.

Despite their advantages, spreadsheets create a shaky foundation for work order history. Spreadsheets require some computer know-how to enter and update data. A non-savvy user could easily mess up columns, rows, and formulas without knowing how to fix it. Data entry in spreadsheets is still very manual and cumbersome.

Another disadvantage of spreadsheets has to do with file access. Some files are locked into a single computer, making it difficult for others to access and see up-to-date maintenance information. Even if files are widely available, only one user can open the file at one time. More worrisome is that users may inadvertently delete or move the file, risking the loss of maintenance data.

Perhaps the biggest drawback of a spreadsheet-based work order management system is the lack of automated work order generation, particularly as it applies to preventive maintenance. Spreadsheet software does not have the ability to automatically generate work order forms based on a schedule. Therefore, work order creation, assignment, scheduling, and distribution remains a very manual process.

In-house Work Order Management System

Organizations that recognize the downfalls of the previous systems mentioned can create their own in-house, “homegrown” work order management systems using database software such as Microsoft Access.

| Pros | Cons |

|

|

The biggest advantage of a homegrown work order management system is customization. While off-the-shelf work order management software products must be design to appeal to many businesses with many different processes, a homegrown system is tailored to the way you work. Depending on the IT resources available, the potential benefit of homegrown systems is virtually endless.

All that being said, developing a work order management system requires a large time and IT investment. Organizations must be able to: create the database, build the software client, install it on servers, host the data, protect and safeguard the code, understand the organization’s maintenance management needs, upgrade hardware and software to support the system, and continually ensure the integrity of the system. Many small to medium sized-businesses simply do not have the manpower to create a work order management system in house.

Adding to the statements above, many homegrown systems are built without the end user experience in mind. The result is that users often find the system too cumbersome to use and inevitably either abandon it or reluctantly accept that more time and effort needs to be devoted to data entry.

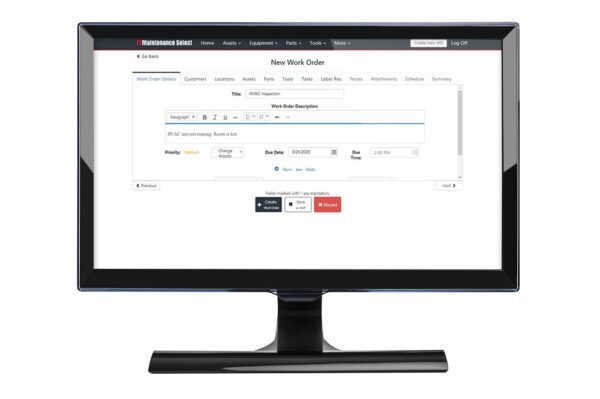

Work Order Management Software

As its name suggests, work order management software is specifically designed for managing maintenance work orders. Because proper work order management relies on information about other maintenance resources, work order management functionality is a central part of computerized maintenance management system (CMMS) software.

| Pros | Cons |

|

|

CMMS software is the most complete work order management system. The benefits of automated work order software can be felt throughout the entire work order management process.

First, it provides requesters with a channel for requesting maintenance assistance. The system notifies administrators of incoming requests, allowing them to review and approve them. Based on the urgency of requests and other maintenance work, the CMMS makes it easy for administrators to prioritize, assign, and schedule work orders.

The CMMS automatically notifies technicians about assigned maintenance work and distributes it electronically, ensuring that work orders don’t get lost. Technicians are able to use an internet-connected device to update work order details and close out work orders once they are complete. A work order list provides technicians with visibility of “open” work orders.

Finally, a CMMS automatically tracks and stores data collected through work orders so that it is available for analysis. Maintenance reports allow organizations to track work order key performance indicators (KPIs), identify trends in productivity and asset downtime, and adjust maintenance plans accordingly.

One of the primary concerns with work order management software is the cost of software and training. On the plus side, many vendors offer subscription licenses to reduce the upfront costs of getting started. To put things further in perspective, the long-term benefits of CMMS software in terms of cost- and time-saving more than make up for the cost of software. For example, consider how much money is saved by reducing asset downtime, even if only by a few hours per year.

Another potential issue is the need to gain employee buy-in. A CMMS represents a new way of doing things, and it is possible that you may face some resistance to the idea of doing things differently. Our article, How to Increase CMMS User Adoption, provides an overview of user adoption challenges and provides some tips on how to deal with reluctant employees.

Manage Work Orders with FTMaintenance

Choosing the right work order management system is an important decision with many factors to consider. It is clear that a CMMS, like FTMaintenance, is the superior choice when it comes to managing maintenance work orders. However, FTMaintenance is more than a simple work order management system. Our full suite of features provides functionality that makes it easy to track assets, MRO inventory, work requests, preventive maintenance, and more. To learn more about FTMaintenance, request a demo today.