Optimizing asset reliability and performance is a critical factor for enabling organizations to generate revenue and achieve other business goals. Therefore, it is important for organizations to understand an asset’s life cycle and identify opportunities to maximize value. This article provides an overview of asset life cycle management.

What is the Asset Life Cycle?

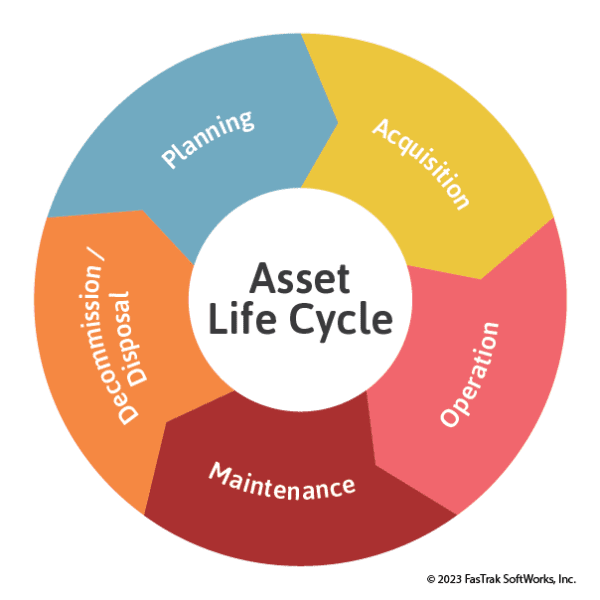

An asset’s life cycle is the series of stages involved in managing an asset, from “life” to “death”. While there are many ways to segment it, fixed assets generally go through 5 main stages:

- Planning

- Acquisition

- Operation

- Maintenance

- Decommission / Disposal

The first stage, planning, represents identifying the need for an asset. The process then continues throughout an asset’s useful life before it is considered to be fully depreciated. Assets are disposed of, recycled, or replaced once they’ve reached the end of their useful life and the process begins again.

Read Also: What is an Asset?

What is Asset Life Cycle Management?

Asset life cycle management (ALCM) is a method of managing assets in order to maximize their value through optimized planning, acquisition, installation, operation, maintenance and disposal. Throughout each stage, organizations look for opportunities to improve productivity, efficiency, reliability, and profitability while reducing risks and related costs.

Organizations invest in ALCM because effective asset management extends an asset’s value beyond its useful life. Further, organizations that continuously collect data throughout an asset’s lifetime gain additional benefits related to making data-driven repair vs. replace decisions, optimizing maintenance plans, reducing asset management costs, and maximizing return on investment (ROI).

Asset Life Cycle Stages

Asset life cycle stages can be defined in multiple ways, but generally fall into the stages described below.

Planning

The planning stage occurs when current assets aren’t meeting the organizations needs. Using data from an asset management system and input from key stakeholders, evaluate the need for the asset, the organization’s current and future needs, and begin researching assets that meet your requirements.

Acquisition

After planning comes the acquisition stage. Acquisition brings focus to your budget and financial situation, as this is when you perform vendor research and ultimately purchase the asset. The information gathered during planning makes it easier to identify a supplier that meets your requirements at an affordable cost.

Also included in this stage is delivery of the asset and installation. Activities include assembly, setup, testing, inspecting, and tracking the asset in your computerized maintenance management system (CMMS) software or enterprise asset management (EAM) software.

Read also: What’s the Difference between CMMS vs. EAM Software?

Meanwhile, the maintenance team can also work with the asset manufacturer to generate a bill of materials (BOM), prepare the maintenance storeroom for new inventory items, and enter spare parts into the CMMS. The maintenance team can also obtain owner’s manuals and set up preventive maintenance (PM) schedules. During installation, technicians may also participate in training from the manufacturer to learn how to perform basic maintenance tasks.

Operation & Maintenance

The operation and maintenance stages represent a majority of the asset’s life cycle. They are grouped together because they happen simultaneously, instead of one after another like the previous stages.

During this period of time, the asset is put into operation and is maintained or repaired as needed. As time goes on, the maintenance team must be mindful of how maintenance needs will change over time.

For example, newer equipment requires fewer repairs, but the risk of unplanned downtime increases as assets age and require more frequent attention. Maintenance activities are also affected by factors such as operator competency, usage, product being handled, availability of maintenance resources, and environmental conditions, to name a few.

The organization will need to perform multiple types of asset maintenance over time. Maintenance strategies differ from one organization to the next – or from one asset to the next – though they typically fall into one of the following categories:

- Corrective maintenance (CM)

- Preventive maintenance (PM)

- Condition-based maintenance (CbM)

- Predictive maintenance (PdM)

Organizations may use one or a combination of these strategies to keep assets in proper working order.

Decommission / Disposal

The last stage in an asset’s life cycle is decommissioning and disposal of the asset. This typically occurs when the asset no longer provides enough value to the organization to justify the costs to maintain it.

Depending on the type of asset and the material it’s made of, it may be recycled or thrown away. In some industries, assets are repurposed before they get disposed of completely. For example, a truck that travels to worksites becomes a plow truck that stays on the property. However, repurposing doesn’t happen often with production assets.

After an asset is disposed, the life cycle starts over again with a replacement asset. This is always a good time to determine if the organization can upgrade to a better product while minimizing costs. By analyzing asset data collected over its lifetime, the organization can reassess how to maximize the next asset’s value moving forward.

Asset Maintenance Management Software

Successful asset life cycle management is built upon the collection and analysis of crucial asset data. Many organizations track asset data in enterprise asset management (EAM) software. For organizations that want to place more focus on the maintenance stage – where asset spend most of their useful life – an EAM might be too complex.

Many organizations implement computerized maintenance management system (CMMS) software to manage maintenance on their equipment and facility assets. CMMS software stores all maintenance data in one spot, allowing maintenance professionals to easily create and manage work orders, view asset history, track demand for spare parts, and much more.

It should be noted, however, that CMMS and EAM software are often used together to get the full benefit of both systems.

Maximize Your Assets’ Useful Lives with FTMaintenance Select

FTMaintenance Select allows you to maximize asset reliability and extend your assets’ useful lives. Our CMMS software links your assets with their related spare parts, maintenance schedules, and work orders to provide a bird’s-eye-view of your asset maintenance needs. Request a demo today to learn more about FTMaintenance Select.