Your assets are the centerpiece of your organization. In today’s economic environment, there is no room for downtime, losses in production, or poor quality. Though maintenance teams are recognized for their ability to keep assets running, businesses try to squeeze as much value out of their assets as possible. Therefore, organizations must practice asset management.

What is Asset Management?

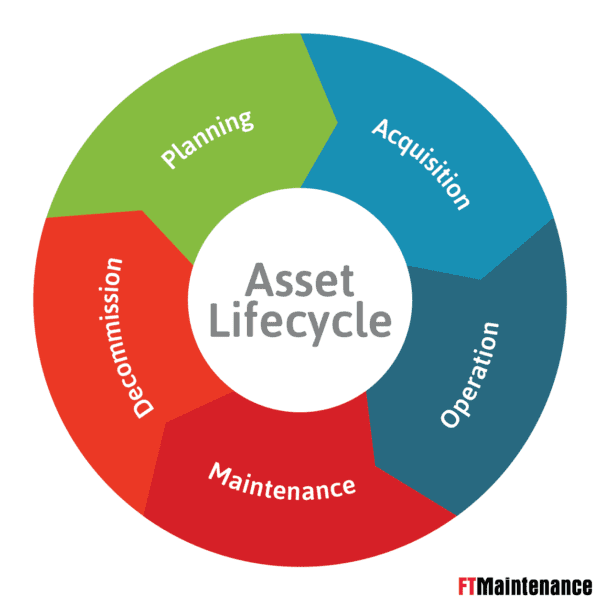

Asset Lifecycle Process

In the finance industry, asset management is related to managing investments. When related to an industrial environment, asset management is the process of maximizing the value an asset provides to an organization throughout its entire lifecycle, in the most cost-effective manner. For this asset management definition, “assets” includes any physical items such as equipment, buildings, vehicles, tools, and property.

Asset Management vs. Maintenance Management

Based on the asset management definition provided, you may have noticed that it sounds very similar to maintenance management. You’re not alone in this observation. Many people use the two terms interchangeably, though they are indeed different.

Since there are many parts of an asset’s lifecycle, asset management involves contribution from multiple departments, such as asset planning, engineering, production, maintenance, and accounting. These groups work together to assess and manage an asset’s cost, value, risk, and performance. Depending on the organization, a single department may be responsible for many of these functions.

Our article, What is Maintenance Management? states that maintenance management focuses on the performance of maintenance activities and the coordination of maintenance resources including parts, labor, and budget. In the graphic above, you can see that maintenance – and therefore maintenance management – is only one piece of the asset management “puzzle.” The following section breaks down asset management into its basic components.

Components of Asset Management

The six main components of asset management are: identification, location, condition, specification, maintenance, and cost.

Identification

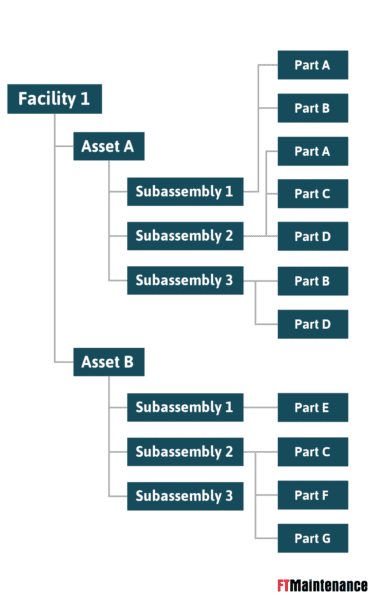

The purpose of asset identification is to know exactly what assets an organization is responsible for managing. While this sounds like common sense, in practice it can be more difficult than one might assume. Organizations may operate multiple buildings in a single location or worldwide, containing hundreds or even thousands of individual assets. A production line functions as a single integrated system, but is typically composed of multiple assets working together. Each of these assets is made up of several subassemblies, which can be further broken down into individual parts.

Given its complexity, companies must find an effective way to organize and store this information. Commonly, an asset registry (listing of assets), an asset hierarchy (nested listing of assets), and/or bills of materials are used.

Asset Hierarchy Example

Recommended Reading: What is an Asset Naming Convention?

Location

It’s not enough to know what assets you have – you must also know where your assets are located. Organizations that work with mobile assets like vehicles, onsite assets, or assets spread across multiple geographic regions should know where their assets are at all times. Graphic information system (GIS) mapping and global positioning system (GPS) technology help maintenance teams easily locate assets and plan future work with location in mind.

Condition

Knowing the condition of an asset is necessary for maintenance and decommission planning. Condition information is obtained through visual inspections or through direct monitoring with dedicated sensors. Additionally, SCADA systems or similar monitoring systems can help you track asset performance. Asset failure can be reported to the maintenance team via a maintenance request system.

Specification

An important component of managing assets is understanding an asset’s design and specification. The specification provides the boundaries for operating assets at maximum efficiency. Asset specification also drives maintenance procedures and ensures proper part replacement and repair. When unexpected breakdowns occur, knowing how assets should perform helps maintenance personnel better identify the cause of failures and return assets to service within its acceptable range for operation.

Maintenance

Once assets are identified and their locations, conditions, and specifications are known, a basic maintenance care plan can be created. Depending on an asset’s current condition, importance, and risk of failure, different maintenance strategies may be employed.

For example, corrective maintenance may be used on production assets that run infrequently and will be relatively inexpensive to fix in case of failure. On the other hand, highly critical assets – such as those that run constantly and whose failure would result in thousands of dollars in lost production – will benefit from comprehensive preventive maintenance.

Given the complexity of managing maintenance plans on hundreds to thousands of assets, organizations invest in a computerized maintenance management system (CMMS). As part of a complete asset management strategy, you can use a CMMS to plan, schedule, and execute maintenance activities that keep assets running. Additionally, CMMS tracks asset service history, including the labor resources, materials, and budget used to complete maintenance activities.

Cost

As stated in our definition, the asset management maximizes an asset’s useful life at minimal cost. As they age, assets become more costly to operate and maintain. Therefore, organizations must be able to monitor actual asset performance and identify areas of cost savings. Generally speaking, regular maintenance is cheaper than replacement.

Maintenance costs include how much maintenance is done, what tasks are performed, and what resources (i.e., labor and parts) are utilized. However, all assets will inevitably reach a point where they become more costly to maintain than to replace outright. In this case, it may be better to replace an expensive asset with a more efficient solution.

A CMMS helps you monitor asset management key performance indicators (KPIs) through maintenance reports. Maintenance management personnel can track performance metrics such as downtime, mean time to repair (MTTR), and mean time between failures (MTBF). Additionally, a CMMS makes it easy to track job completion, determine the percentage of corrective maintenance versus preventive maintenance, keep an eye on the backlog, and much more.

Manage Your Assets with FTMaintenance

Maintenance management is necessary for effective asset management, especially in asset-intensive industries such as oil and gas, power and energy, and water and wastewater. Because of its impact on the organization, there must be a system in place for tracking and managing vital asset information.

FTMaintenance computerized maintenance management software (CMMS) stores all of your asset information in one place, allowing you quickly find what you need. Combined with other maintenance management features, you’ll be able to create detailed maintenance plans and make data-driven decisions about the management of your assets. Learn more about the capabilities of FTMaintenance asset management software.