Effective equipment management is the key to reliable production, reduced downtime, and extended asset life. However, many organizations struggle to properly manage their equipment, causing a ripple effect that negatively affects productivity and profitability. But what if these challenges could be minimized? By adopting equipment management best practices, maintenance teams can ensure equipment reliability and operational success. This article provides an overview of best practices to help you take your equipment management practices to the next level.

| This article is part of a series of articles related to maintenance management best practices. Read our other best practice articles: |

Why Equipment Management Matters

Equipment management is a critical component of a well-run maintenance operation. When done correctly, it leads to:

- Lower Equipment Costs: Strictly managed and maintained equipment is less likely to undergo unexpected failures, reducing the need for emergency repairs and costly unplanned downtime.

- Boosted Productivity: Reliable equipment ensures that organizations can maintain consistent operations and meet production deadlines with minimal disruption.

- Extended Asset Lifespans: Proactive, scheduled maintenance helps prevent excessive wear and tear, maximizing a machine’s useful life and delaying the need for costly replacements and repairs.

- Enhanced Safety: Effective equipment management mitigates potential risks and fosters a safer working environment.

- Regulatory Compliance: Detailed equipment and maintenance documentation helps organizations meet regulatory requirements and avoid penalties and liability.

- Better Decision-Making: Comprehensive equipment records provide valuable insights into performance, helping teams prioritize tasks and allocate resources.

In short, effective equipment management is not simply a suggestion – it is necessary for supporting the day-to-day and long-term goals of industrial organizations.

Equipment Management Best Practices

Maintenance organizations must adopt equipment management best practices to create a structured approach that enables them to maximize asset value, leverage performance data, and improve decision-making. While there are numerous best practices to consider, the following section highlights the most widely accepted tactics.

Invest in Equipment Management Software

Longstanding barriers, such as the perception of maintenance as a cost center, a reactive maintenance culture, and budget constraints have made organizations reluctant to invest in maintenance technology. However, as equipment becomes more complex, and organizations recognize the critical role of maintenance in minimizing downtime and controlling costs, attitudes have changed.

Today, organizations are investing in solutions that will empower them to operate more efficiently and maximize the value of their equipment at every stage of its lifecycle. There is a wide range of solutions available, of which computerized maintenance management system (CMMS) software and enterprise asset management (EAM) software are the most common. Systems such as these centralize equipment information, providing instant access to critical data that allows you to automate maintenance schedules, allocate resources, and analyze performance to make data-driven decisions.

Inventory and Identify Your Equipment

To effectively manage equipment, you must have visibility of what equipment you have and where it is used or stored. To do this, maintenance teams create an asset register that lists every piece of equipment and its location. This ensures that every piece of equipment is accounted for, ensuring that none are overlooked for inspections, scheduled maintenance and repairs, or in reporting.

Further, it is critical that each piece of equipment is uniquely identified so that it is not confused with other, similar equipment and that maintenance activities can be linked to specific machines. Many companies create or follow an asset naming convention to generate meaningful ID numbers and provide a structure for future equipment identification. Our article, Asset Naming Conventions: The Complete Guide, discusses multiple approaches to developing your naming convention.

Prioritize Your Equipment

Not all equipment contributes equally to business operations. That’s why it is important to prioritize equipment based on factors such as importance to core business functions or production processes, downtime cost, costs, and safety risks. Doing so allows you to put more focus on equipment that matters most to your organization and make strategic decisions about the maintenance frequency, labor resources and required skills, budget, and spare parts inventory devoted to critical equipment.

Create and Maintain Comprehensive Equipment Records

Creating and maintaining accurate and up-to-date equipment records is essential for effective equipment management. These records store critical information about your equipment, such as their location, warranty information, related vendors and suppliers, and performance data. A CMMS allows you to attach electronic files, like owner’s manuals and schematics, to records so they are readily available.

However, simply creating the records isn’t enough – keeping them up to date is equally important. As maintenance activities are performed, it’s crucial to update equipment records to ensure your team is always working with the most current information available. Equipment management software can automatically update records for you, such as attributing maintenance costs from work orders, generating a bill of materials based on repairs, tracking downtime, and more.

Understand the Big Picture

It can be common for maintenance teams to treat each piece of equipment as an individual, standalone unit. However, equipment often works as part of a large system, and treating each unit independently can cause teams to overlook how performance and failures affect others. Organizing equipment into an asset hierarchy that shows parent-child relationships helps maintenance teams understand equipment’s broader role in operations, and makes it easy to visualize the relationships between equipment, their subassemblies, bills of materials, and related components.

Identify and Stock Critical Spares

Critical spares are the parts most likely to cause significant downtime if they are unavailable when needed. For each piece of equipment, identify critical spares on the bill of materials and ensure these parts are kept in stock with proper inventory management support to maintain availability. A CMMS can simplify inventory management by tracking stock levels in real time and sending reorder notifications. By setting minimum stock levels and reorder point triggers, you can ensure timely restocking and avoid unexpected shortages.

Gather Baseline Performance Data

In addition to equipment details such as operating specifications and service history, maintenance teams should also collect some baseline data such as downtime, mean time between failures, replacement costs of parts, and technician’s response times. Doing so provides maintenance teams with valuable insights into machine performance, and establishes a benchmark against which you can measure improvements over time. These measurements may also prompt a change in maintenance strategy or help justify equipment replacement.

Develop a Preventive Maintenance Program

Developing a preventive maintenance (PM) program is a critical component of equipment management because it transitions maintenance teams from a reactive approach to a proactive strategy. A formal preventive maintenance plan provides structure and consistency in maintenance activities, and guides when maintenance should be performed, who should perform it, and what should be done. Base your PM program off of manufacturer recommendations and maintenance history, but be sure to adjust according to performance or operational changes.

Preventive maintenance planning and scheduling is where CMMS software really shines. An effective CMMS allows you to create work order templates for recurring maintenance work, ensuring that work is performed consistently and to the same standard each time. Flexible scheduling options allow you to automatically generate work orders by date-based or usage-based triggers, ensuring that maintenance is only performed when needed.

How CMMS Software Supports Equipment Management Best Practices

As mentioned throughout this article thus far, CMMS software increases your ability to implement and maintain equipment management best practices in ways that are just not possible using manual methods. Below are some ways a CMMS supports effective equipment management.

Centralized Equipment Data

CMMS software provides a centralized database that stores all information about your equipment in one location, serving as a sole source of truth for your maintenance team. From technical specifications to images, videos, and digital copies of owner’s manuals, the system allows you to access critical equipment information the moment you need it. This eliminates time wasted rifling through file cabinets or other systems for information.

Additionally, cloud-based CMMS software provides remote access to equipment data, ensuring your team has the information they need wherever they go.

Visualization of Equipment Relationships

Many CMMS solutions feature an asset hierarchy, showing the relationship between equipment and their related subcomponents in a tree view. These hierarchies not only help you visualize your equipment’s place within the facility, but allow you to pinpoint problem areas quickly and prioritize maintenance activities to areas of need.

Detailed Equipment Records

CMMS software allows you to log and organize detailed records for all of your managed equipment. These records encompass the entire asset lifecycle, including identification details, technical specifications, maintenance history, work order details, part usage, and vendor information. By integrating equipment records with other critical maintenance data, a CMMS provides you with a complete picture of your equipment’s performance and repair activity.

Spare Part Inventory Management

Successful equipment maintenance relies on equally successful spare parts management. A CMMS integrates these functions seamlessly, allowing you to identify the parts used to repair equipment and track their availability in real time. As parts are consumed through work orders, the system automatically updates inventory levels and notifies you when it’s time to reorder. This ensures that critical spares and other parts are available when – and before – you need them.

Automated Preventive Maintenance Scheduling

Maintenance scheduling software, like a CMMS, is essential for streamlining and automating your preventive maintenance program. A CMMS allows you to create a master preventive maintenance plan tailored for each piece of equipment, ensuring that maintenance tasks are scheduled at the right time based on manufacturer recommendations, usage patterns, or historical performance. As you collect data, you can fine-tune the schedule to minimize disruptions to daily operations and take advantage of opportunities for more comprehensive maintenance needs.

Equipment Performance Tracking

Tracking equipment in a CMMS allows you to make data-driven decisions about your equipment. Reporting and dashboard features make it easy to visualize and track the performance of your equipment, allowing you to identify trends and detect patterns in performance. With this data readily accessible, you can better identify which equipment is susceptible to failure and requires extra attention, or justify repair vs. replace decisions.

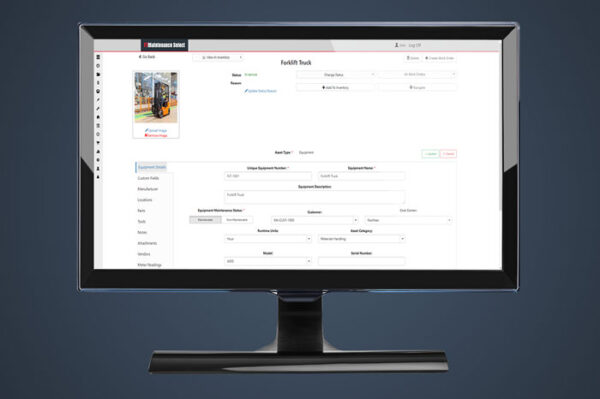

Improve Your Equipment Management Practices with FTMaintenance Select

Effective equipment management is essential for minimizing downtime and maximizing the value of your equipment and maintenance assets. By implementing best practices – in particular, investing in a CMMS – you can significantly improve your equipment management efforts.

A CMMS like FTMaintenance Select provides the tools necessary for documenting, tracking, and analyzing equipment performance and status, and empowering you to take a proactive approach to equipment maintenance. Request a demo today to see how FTMaintenance Select can improve your equipment management practices and provide value to your organization.