Many maintenance teams tend to follow a reactive maintenance approach due to its low initial costs and low requirement for planning. After all, it’s easier to do nothing than something. Unfortunately, a “fix it when it breaks” approach sends technicians scrambling, and often results in overtime, high repair costs, lost production, and severely reduced asset life. These consequences run counter to an organization’s goals of asset availability and profitability.

Even though many organizations realize that it is better to prevent breakdowns rather than respond to them, they struggle to be proactive about asset maintenance. This article seeks to provide a framework on how to implement a proactive maintenance strategy.

What is Proactive Maintenance?

Proactive maintenance is a maintenance strategy that involves performing maintenance before a failure or breakdown occurs. It seeks to increase asset availability, reduce downtime, and lower maintenance costs by addressing the root causes of asset failure before significant problems occur.

Proactive vs. Reactive Maintenance

Reactive maintenance is a maintenance strategy that involves restoring assets to operating condition after a breakdown (failure to function) has occurred. Compared to proactive maintenance, reactive maintenance requires less planning and upfront costs, at the expense of higher overall maintenance costs, increased downtime, and unpredictability.

A reactive maintenance strategy is designed to treat the symptoms of asset failure to promptly return a failed asset to full working order rather than diagnose and analyze why failures occurred. Generally, reactive maintenance traps maintenance teams in a vicious cycle of constant emergency work due to the nature of unexpected failures, leaving less time and money for maintenance work that could have helped to avoid the same failure in the first place.

By comparison, proactive maintenance works by focusing on the root causes of failures and then taking proactive actions to minimize or eliminate them. Though a proactive maintenance strategy requires more planning and upfront investment than reactive maintenance, it is more targeted, predictable, and cost-effective. In fact, by some estimates, proactive maintenance can lower total maintenance costs by as much as 60%.

It is important to recognize that reactive maintenance will never go away completely. In some cases, it is more economical to let parts fail rather than proactively replace them. Additionally, no maintenance strategy will eliminate unexpected failures. A balanced maintenance plan will include and budget for some reactive maintenance.

Further Reading: Using Root Cause Analysis to Improve Maintenance

Types of Proactive Maintenance

There are many types of proactive maintenance:

- Planned Corrective Maintenance (CM): Maintenance that is required to restore an asset to optimum or operational condition, but does not need to be performed immediately. Planned corrective maintenance occurs when a maintenance need is expected, allowing you to schedule corrective action ahead of time.

- Preventive Maintenance (PM): The most common type of proactive maintenance. Preventive maintenance is scheduled using time-based or usage-based intervals.

- Condition-based Maintenance (CbM): Maintenance carried out when an asset’s monitored condition reaches an unsatisfactory level. Using real-time condition data, maintenance can be performed before failure occurs.

- Predictive Maintenance (PdM): Maintenance scheduled using predictive analysis, based on an asset’s monitored condition, historical performance data, and advanced analytics. Predictive maintenance forecasts when failure is likely to occur, allowing maintenance teams to take preventative action.

Laying the Groundwork for a Proactive Maintenance Strategy

The transition from reactive maintenance to proactive maintenance does not happen overnight. Think of it more as an evolution rather than a flip of the switch. The following sections outline a few key tasks that will help you build a strong foundation for change before you actually begin to implement a proactive maintenance strategy.

Get Ready for Change

The truth is most people don’t like change. Transitioning to a proactive maintenance strategy requires a change in maintenance culture, which can be a challenge. Satisfaction with the status quo and reluctance to change are difficult hurdles for organizations to overcome, but it can be done.

A change in strategy also brings about the use of new technology, additional employee training, and other tools. It is crucial that the maintenance team embraces these opportunities. You will have an easier time implementing a proactive maintenance strategy if everyone is on board.

Invest in Maintenance Management Software

The best way to support a proactive maintenance strategy is with a computerized maintenance management system (CMMS). A CMMS helps you and your team shift to a proactive mindset by allowing you to organize, track, manage, and analyze maintenance data.

As you craft your proactive maintenance plan, a CMMS will allow you to easily establish preventive maintenance procedures, track asset failures and service history, and leverage maintenance reports to optimize proactive maintenance schedules.

Later, when your plan is put into action, a CMMS will keep your team accountable. Team members will use the CMMS to communicate maintenance work, access asset information, and document maintenance activities. If you are not currently using a CMMS, it is time to invest.

Further Reading: Creating a Culture of Accountability with a CMMS

Assess Your Current Maintenance Operation

Evolving maintenance operations must naturally move in a proactive direction. While maintenance teams in many organizations operate in a reactive way, they often quickly realize that this approach is not sustainable or beneficial. Additionally, an organization’s financial goals rely on improved asset reliability and availability, creating a greater demand for a proactive maintenance strategy.

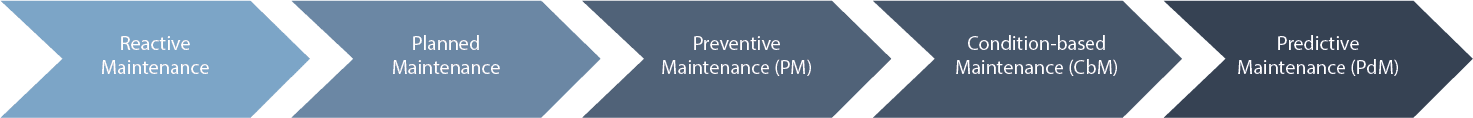

The graphic above depicts the general progression of maintenance operations. Take a moment to identify where your organization currently falls and what’s next. As you progress down the line, consider what other changes are needed to support your operation.

Each level of complexity requires a higher level of skill, increased asset knowledge, and time and effort to plan and schedule maintenance than the last. Consider whether you currently have the technology, staff, and other resources required to move on. If not, work with your organization to determine how each can be acquired.

Understand Your Current Performance

In order to make improvements to your maintenance operations, you must have a solid understanding of your current performance. Performance data should be gathered from multiple sources such as the operations and engineering department, and your maintenance documentation system or CMMS. If you don’t have a maintenance documentation system in place, obtaining some of this information will be very difficult, if it exists at all. Therefore, we strongly recommend implementing and tracking maintenance activities in a CMMS.

Measures of performance include asset availability and the use of maintenance resources. In terms of asset availability, it is important to understand when downtime occurs, how long it lasts, and what causes it. Organizations commonly use asset management key performance indicators (KPIs) such as Mean Time Between Failure (MTBF), Overall Equipment Effectiveness (OEE) , and others to assess availability.

Evaluating maintenance resources involves knowing where time and money are spent. For example, it is important to know asset repair costs, how technicians spend their time, how much money is wasted on avoidable emergency inventory orders, and so on.

How to Implement a Proactive Maintenance Strategy

Once sufficient asset and historical maintenance information is collected, you can proceed with implementing your proactive maintenance strategy. The following steps provide a framework to help your implementation go smoothly.

Select a Project Leader

One of the most important keys to success is selecting an effective team member to spearhead the project. Ideally, the project leader will be someone who has intimate knowledge of maintenance needs, such as a maintenance supervisor, maintenance scheduler/planner, maintenance manager, or inventory clerk.

The project leader is tasked with overseeing the planning and implementation processes and ensuring tasks are completed. Their responsibilities include managing day-to-day operations, gathering information, and eventually creating and managing the maintenance schedule. The project leader also ensures that others are adhering to the proactive maintenance plan and properly using the CMMS.

Involve Key Stakeholders

Asset maintenance affects the entire organization. Therefore, an effective proactive maintenance program is one that receives input from and informs multiple maintenance stakeholders. Stakeholders may include the following:

- Front-line maintenance technicians responsible for performing the actual maintenance tasks who can provide information about ongoing equipment issues and downtime events. Technicians are also responsible for tracking maintenance activities in the CMMS, helping you build valuable data.

- Production operators who are responsible for ensuring that assets are running to specification. These regular equipment users who know what everything looks like when it’s “in place” and act as important allies for detecting issues early. Further down the road, they can assist with simple preventive maintenance activities or minor repairs.

- Operations engineers in charge of purchasing new assets, planning new equipment lines and cells, and performing critical analysis. This group also documents equipment specifications and may provide parts lists to the maintenance department.

- Operations management that communicates concerns about asset availability and scheduling.

- Safety managers who oversee employee health, safety, and environmental risks.

- Original Equipment Manufacturers (OEMs) who design industrial equipment and facility assets. OEMs are a valuable source of information and typically provide performance parameters and recommended maintenance schedules.

- Upper management who commits resources to the project and expect to see results.

Each of these stakeholders plays a role in optimizing and enhancing the proactive maintenance plan.

Create an Asset Registry

An asset registry is a list of all the assets that you are responsible for maintaining. Creating an asset list ensures that records are up to date and that all assets are accounted for when planning maintenance. A CMMS stores important asset information and makes it easy to track maintenance performed on each asset.

Learn more about FTMaintenance Asset Management

Identify Critical Assets

Critical assets are assets that are integral to business operations and result in major consequences should they break down. Determining an asset’s criticality helps you prioritize where to focus proactive maintenance efforts. It makes sense that the more critical the asset is to the organization, the more should be done to protect it.

Typically, critical assets are well-known throughout the organization. Regardless, it is beneficial to cross-check with other stakeholders to ensure that everyone is in agreement as to which assets are considered critical. In larger organizations, critical assets may be formally identified by the operations engineering team through a criticality analysis – a systematic way of evaluating the risk of asset failure.

Determine Effective Maintenance Activities

Once critical assets are identified, determine the best way to keep them running. At this stage you can keep things high level, but should at least determine the type of maintenance to be performed and how often. Later, you can hash out the specifics of what each task entails.

The goal for now is to get a rough sense of how you will care for each asset. An effective proactive maintenance program will leverage numerous resources, including:

- Maintenance history (CMMS or other internal maintenance documentation)

- Input from key stakeholders

- Documentation from criticality analyses

- Maintenance specifications provided by OEMs

- Operational experience

If just getting started with proactive maintenance, your plan will likely consist of planned maintenance, time-based preventive maintenance, and usage-based preventive maintenance. Advanced organizations may utilize condition-based and predictive maintenance.

Create Detailed Instructions

With effective maintenance strategies defined and maintenance activities identified, now you can create documentation about how each activity should be performed. Developing task-specific, step-by-step instructions provides guidance for technicians and ensures proactive maintenance is performed consistently. Be sure to estimate the amount of time needed to complete each task, as it will be important to make sure that your proactive maintenance schedule is realistic. Use your CMMS to create and manage detailed task lists for use on proactive maintenance work orders.

Create the Proactive Maintenance Schedule

The first step to creating the proactive maintenance plan schedule is to decide on the official start date of the program. Then, assign maintenance activities to specific days using the frequencies and estimated duration identified earlier.

A schedule that is mapped out for at least one year should allow you to balance the workload and account for at least one cycle of maintenance activities with less frequent occurrences. Ultimately though, the best duration will depend on your organization.

When scheduling work, consider peak production periods or planned plant shutdowns. These events may require changes to an otherwise rigid maintenance schedule.

Implement the Proactive Maintenance Plan

Now is the time where all the pieces come together. Once the start date arrives, your plan can be put into action. Don’t panic if things don’t go exactly as planned right out of the gate. Proactive maintenance plans will constantly change based on experience, updated recommendations, new technology, and so on.

Remember that implementing a proactive maintenance strategy is an evolution, and will take weeks to months to fully implement. The implementation timeframe depends on the resources at your disposal. Regardless, any step towards proactive maintenance – no matter how small – is beneficial.

Implement Proactive Maintenance with FTMaintenance

As demonstrated many times throughout this article, a CMMS is an essential tool for helping organizations move from a reactive mindset to a proactive maintenance culture. Leveraging CMMS software will make the implementation and tracking of your proactive maintenance plan go smoothly.

FTMaintenance is a powerful CMMS solution that offers robust asset management, preventive maintenance, and maintenance reporting features that allow you to craft an optimized proactive maintenance plan. Schedule a demo of FTMaintenance today!

Recent Comments