Maintenance management in the food and beverage industry is unlike that of any other industry. Complex, interconnected assets are used to produce products that must have a consistent quality and be safe to consume. Frequent cleaning introduces a wet environment that accelerates equipment degradation and puts food and employee safety at risk. On top of this, food processors must adhere to considerable regulatory requirements as well as consumer and societal expectations.

Given these unique circumstances, organizations must closely manage maintenance operations. This article describes how food and beverage manufacturers can use computerized maintenance management system (CMMS) software to address common food processing plant maintenance challenges.

The Role of Maintenance in Food and Beverage Manufacturing

Though generally viewed as a “necessary evil,” maintenance management in the food industry significantly impacts the bottom line. Asset-intensive industries like food processing rely on asset uptime to generate revenue. Breakdowns and bottlenecks in continuous production processes create a domino effect that can lead to considerable losses for the organization.

Effective food processing plant maintenance enables the organization to maintain or achieve greater levels of production, and therefore, greater levels of revenue. Maintenance teams support these goals by maximizing and optimizing asset reliability through carefully managed maintenance operations.

Additionally, maintenance teams must preserve assets operating in extremely hot, cold, and wet conditions; adhere to food safety, occupational safety, and other regulations; while minimizing food waste. This must all be done at minimal cost to the organization.

Challenges of Maintenance in the Food Industry

Managing maintenance in the food industry is easier said than done. Food and beverage manufacturers face multiple maintenance management challenges unique to food and beverage production.

Strict Regulatory Requirements

Since their products are meant to be consumed, food and beverage manufacturers must comply with multi-layered standards and requirements from multiple regulatory agencies. For example, in the United States, food manufacturers are subject to regulations from the following government organizations:

- Food and Drug Administration (FDA)

- United States Department of Agriculture (USDA)

- Occupational Safety and Health Administration (OSHA)

- United States Environmental Protection Agency (EPA)

Additionally, some organizations seek accreditation from standards-setting bodies such as the International Organization for Standardization (ISO) and Safe Quality Food Institute (SQF). Organizations that do business internationally may also be subject to international regulations, which differ from country to country.

Due to strict regulatory requirements, compliance should be a focus of all maintenance-related projects. Maintenance audits can occur at any time, so food processing plant maintenance must be done “by the book,” or else face consequences.

Complex Equipment

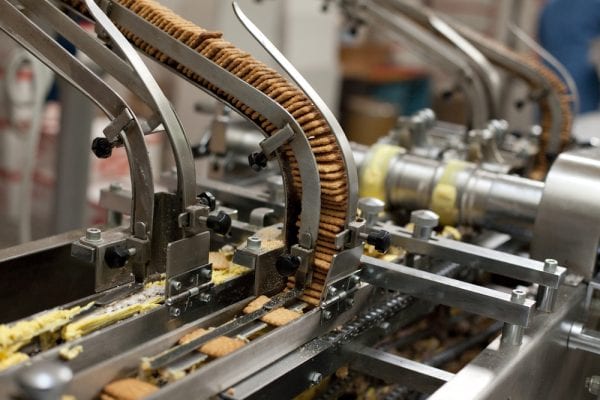

Equipment in the food and beverage industry is complex, interconnected, and in many cases, run continuously. Production lines are a network of automated, specialized machinery connected together through a system of conveyors and belts. Continuous manufacturing processes require that every piece of equipment keeps up with one another – otherwise, the entire production line halts.

At the end of the production line is packaging. Packaging equipment is highly sophisticated due to forming irregularly shaped boxes, applying labels in precise locations, handling unique packaging materials, and moving goods in a non-linear path at high speed. Specialized training, including an intimate understanding of the equipment’s mechanical and electrical systems, is often required to diagnose failures and perform maintenance.

In addition to being complex, food processing equipment is also old. Studies suggest that most food manufacturers are using equipment that is 20 years old or older. This indicates that organizations prefer to invest in strategies to extend an asset’s useful life rather than replace assets. These factors place a lot of pressure on the maintenance department to be effective.

Wet Environments

Food processing plants are extremely hygienic environments. However, frequent cleaning and sanitation creates wet environments that introduce additional risk.

Water and chemicals, dispersed through high-pressure jets, wreak havoc on equipment. Heavy-duty cleaning apparatuses strip away coatings and paint on machine exteriors, leaving them susceptible to rust and corrosion.

Control panels and electrical components are sealed to protect against moisture, and make equipment more costly to install and maintain. Voids and recesses in equipment collect water and create breeding ground for bacteria and other pathogens.

Wet environments pose a threat to employee safety as well. High-power water jets and super-heated steam can cause bodily harm if workers aren’t careful. Wet floors and surfaces are major slip-and-fall hazards. Extreme heat or cold from equipment, combined with moisture, creates suffocating humidity, scalding steam, and slippery, icy surfaces.

Food Safety and Sanitation

Due to their frequent interaction with food-contact surfaces, maintenance personnel run a high risk of contaminating food products. For example, dirty, greasy hands may be placed on surfaces that touch food. Standing on or leaning over machinery causes hair, dirt, and debris to fall into food processing machines if not properly covered. Small parts can be misplaced or accidentally fall into product.

Since there are many potential sources of contamination, maintenance personnel must keep food safety top-of-mind at all times. Facilities where food products are produced, packaged, or stored should be well maintained and free of pests and harmful waste. Employees must wash hands and equipment thoroughly, wear clean protective clothing, and cover hair.

An organization’s sanitation regimen can also interfere with maintenance work. In some organizations, the maintenance team assists with sanitation, taking technicians away from their primary responsibilities. Some maintenance tasks, like inspections or calibrations, can be done during sanitation downtime. However, activities such as electrical work cannot be performed during this time due to the wet environment.

In a rush, it is easy for employees to forget or ignore food safety practices. Failure to uphold proper hygiene requirements may result in contaminated food, infections, outbreaks, and potential lawsuits.

Food Waste

Asset downtime not only backs up production, but can cause significant food waste. For example, bacteria quickly grow on food that is not kept at the proper temperature and humidity. Heat and cold, combined with moisture, creates a breeding ground for microbial contaminants. The longer food remains in undesirable conditions, the more it is at risk for spoilage. As a result, product must be scrapped due to health and safety concerns. Therefore, maintenance teams are compelled to work as quickly as possible to prevent losses.

Benefits of CMMS for Food Manufacturers

One way organizations tackle the challenges of maintenance in the food processing industry is a well-implemented maintenance program supported by a computerized maintenance management system (CMMS). CMMS software centralizes maintenance data, automates tasks, and records details about your assets and maintenance activities. Below are just some of the reasons food and beverage manufacturers need to invest in a CMMS.

Implementing Proactive Maintenance

For food and beverage manufacturers, a reactive, run-to-failure maintenance strategy is not a viable option. In the food industry, production is sensitive to downtime, contamination, and waste. Proactive maintenance, where maintenance is performed before failures and breakdowns occur, is a better solution.

CMMS software supports a proactive maintenance strategy by making it easy to plan, schedule, and track preventive maintenance (PM) activities. Maintenance staff can use the system to create PM task lists and check part availability – or requisition parts, if needed.

Real-time information about asset availability and maintenance labor resources allow personnel to optimize maintenance schedules. A CMMS generates PM work orders automatically based on the selected schedule, ensuring that maintenance work doesn’t fall through the cracks.

Sophisticated organizations use CMMS to support condition-based maintenance (CbM) or predictive maintenance (PdM) programs. These approaches make use of sensors and other diagnostic tools to provide real-time condition data that helps maintenance teams identify impending failure. In the case of predictive maintenance, analysis software is used to estimate when equipment will fail based on the asset’s history and current condition.

Each of these methods further reduces downtime by allowing maintenance to be performed only when needed. CMMS allows you to track CbM and PdM maintenance activities and easily adjust maintenance schedules.

Learn more about How to Implement a Proactive Maintenance Strategy.

Storing Maintenance Documentation

A big advantage of CMMS software is the ability to document maintenance activities and access critical documentation from a single system. Over time, completed work orders build maintenance history that provided details about what work was done, when it was done, and who did it. Reporting features organize and analyze data to help you track key performance indicators (KPIs) and assist with smarter decision-making.

CMMS software makes vital maintenance documentation such as user manuals, safety procedures, warranties, and other essential information quickly available. Employees can also supplement maintenance records with visual data like images and videos.

Documenting Maintenance Procedures

Maintenance is most effective when everyone performs it the same way. CMMS software allows you to create task lists that describe maintenance activities step-by-step. For example, maintenance managers may assign a task to technicians to account for all parts and/or debris after repairs are complete. Doing so will ensure that these materials don’t find their way into food products.

Meeting Regulatory Requirements

Regulated industries use CMMS to provide regulators and auditors with the maintenance documentation necessary to prove compliance.

For example, the CMMS can be used to create and store checklists that ensure employees follow proper maintenance procedures. Digital signatures and approvals help organizations verify that work is complete and produces the intended results. Work order history records provide proof that repairs took place. With a CMMS, there is no reason to fear maintenance audits.

Keeping Up with Maintenance Needs

The need for maintenance can spring up at any time. A quality CMMS allows both maintenance and non-maintenance employees to contribute to food processing plant maintenance.

Non-maintenance employees notify the maintenance team of needed repairs through maintenance work requests. Using a web-based form or mobile application, employees send requests directly to the maintenance team, where they are reviewed. Valid requests turn into work orders that are added to the job list. The CMMS notifies requestors when their requests are complete.

Mobile capability allows technicians to take the CMMS with them on an internet-connected mobile device. As workers go about their daily routine, the mobile CMMS is used to created service requests and work orders. Mobile CMMS makes technicians more productive by allowing them to update and close work orders from the field.

Optimize Food Processing Plant Maintenance with FTMaintenance

The food and beverage industry faces many maintenance management challenges. In today’s competitive landscape and highly automated manufacturing environment, effective maintenance management provides a major advantage to organizations in the food industry. FTMaintenance is a robust CMMS solution that provides a single platform for managing, documenting, and tracking maintenance activities and resources. Request a demo today to learn how FTMaintenance can optimize your maintenance operations.

Read more about FTMaintenance Select benefits for the food and beverage industry

In many organizations, the word “audit” evokes feelings of annoyance, anxiety, and fear. In reality, audits are not as bad as they are made out to be. By understanding how maintenance audits work, you will see why maintenance audits are nothing to fear, especially if you are using

In many organizations, the word “audit” evokes feelings of annoyance, anxiety, and fear. In reality, audits are not as bad as they are made out to be. By understanding how maintenance audits work, you will see why maintenance audits are nothing to fear, especially if you are using

Recent Comments