FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.4.5.1.0, which incorporates the following:

Solutions

- Work Order Management

- Expanded support for special characters for Non-User Approver passcodes.

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.4.5.1.0, which incorporates the following:

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.4.5.0.0, which incorporates the following:

Features

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.76.4.0, which incorporates the following:

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.76.2.0, which incorporates the following:

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.76.1.0, which incorporates the following:

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.76.0.0, which incorporates the following:

Features

Solutions

Accurate maintenance data is critical for the success of any computerized maintenance management system (CMMS). Industrial organizations invest in CMMS software to increase efficiency, improve asset reliability, and reduce maintenance costs. However, the urgency of implementation often leads teams to overlook critical tasks, such as reviewing their current maintenance data before entering it into the system.

As a result, bad maintenance data is entered into the system from the start, disrupting maintenance operations and setting your team up for failure. In this article, we’ll examine how CMMS data quality directly impacts maintenance operations and explain why reliable maintenance data is essential for effective maintenance management.

CMMS data quality is the extent to which information in a CMMS accurately reflects the real-world entities it represents. It is a measurement of how well maintenance records correctly document and reflect the true state of assets, inventory levels, and resource availability.

High-quality CMMS data is critical for making informed decisions related to asset lifecycle management, maintenance scheduling, resource allocation, and other maintenance management processes. Poor-quality data makes decisions more difficult and leads to real-world consequences. For example, a Gartner report estimates that organizations lose an average of $12.9 million (USD) each year due to poor quality data.

Recognizing poor-quality CMMS data is easier said than done. Within a dataset containing hundreds to hundreds of thousands of records, it can be difficult to distinguish the “bad” data from the “good” data. So, how can you evaluate the quality of your data?

CMMS data quality is measured by comparing the condition of your maintenance data to an ideal state. High-quality data is commonly defined by the following characteristics:

High-quality CMMS data provides a strong foundation for informed decision-making, ensuring you can rely on facts rather than gut feel, make better recommendations, and strengthen your credibility within the organization.

On the surface, a little compromised data in your CMMS may seem like a minor issue. After all, could it really be that bad? To put it simply, yes. Even small errors and inconsistencies can have big implications and lead to costly consequences. Let’s look at a few examples of bad maintenance data and the ripple effect it has on operations.

Suppose an asset is entered into the CMMS multiple times under different record IDs. When users encounter the duplicated records, they choose one using their best judgment or out of convenience.

As a result, work order history and downtime is tracked across multiple records, both of which provide an incomplete picture of asset performance and maintenance needs. From a planning perspective, duplicate records may result in redundant preventive maintenance being scheduled for the same asset, wasting valuable time and resources. KPI reports may also show misleading information about your assets.

When an asset or piece of equipment is not entered into the CMMS at all, maintenance activities may go untracked. For example, critical equipment that isn’t recorded won’t have scheduled preventive maintenance, and any repairs may not be logged. This leads to gaps in maintenance history, unexpected downtime, and flawed reports, making it difficult to allocate resources or avoid unexpected downtime.

Every maintenance department has dealt with the consequences of inaccurate inventory data. Outdated or inaccurate stock levels can lead to too much or too little inventory on hand, both of which present challenges for maintenance teams.

When a CMMS incorrectly shows low stock for a part, it triggers purchasing activity – even though the part is actually available. This reordering results in overstock, which ties up money and takes up physical space in the stockroom. Worse yet, excess parts may become obsolete before they are used.

On the other hand, stockouts can occur when the CMMS indicates that a part is available when it is in fact, not. This mismatch leads technicians to assume parts are available, only to discover they are not in stock when needed.

As a result, the organization incurs unnecessary costs due to excess downtime and emergency orders with premium shipping fees. Stockouts are especially problematic for highly specialized parts, which may have long lead times for replenishment.

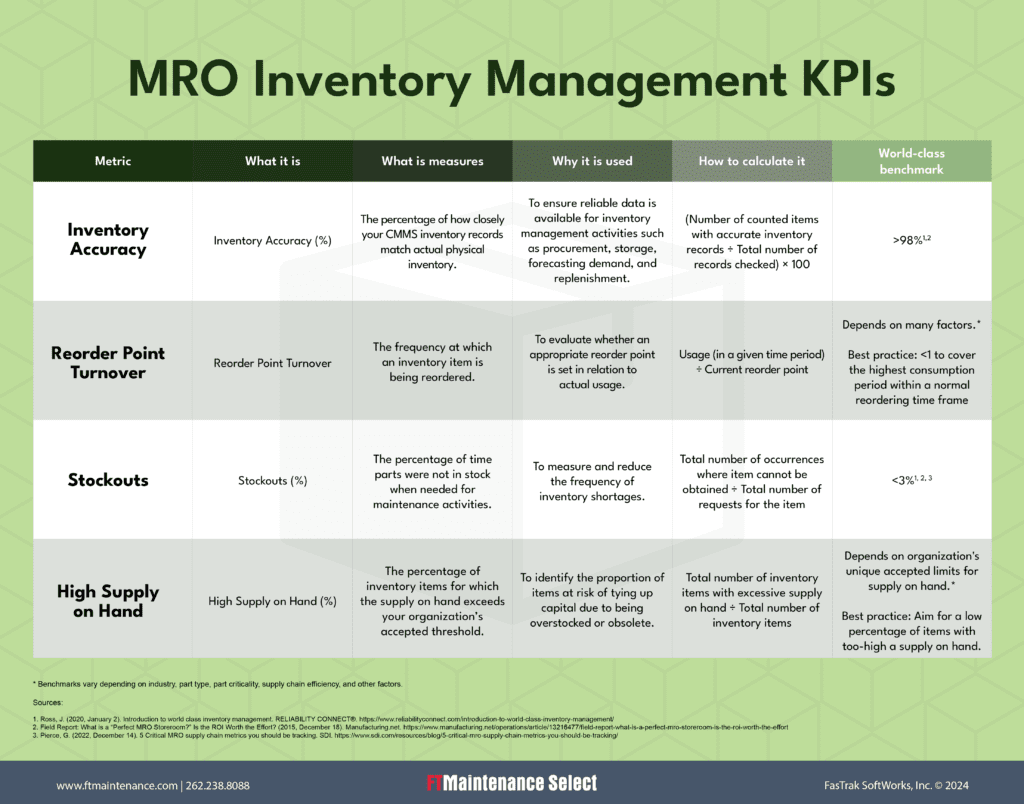

Learn more about MRO inventory KPIs to improve spare part management

Errors such as incorrect task details, missing completion dates, or improperly logged labor hours can disrupt operations. For example, if a routine inspection is marked complete without documenting the actual work performed, technicians may repeat the same task unnecessarily.

Conversely, if a required task is skipped or recorded incorrectly, equipment may fail prematurely. This can lead to unexpected downtime, higher repair costs, and potential safety risks. These mistakes and omissions make it harder for teams to assess performance, plan maintenance schedules, and identify recurring issues.

Organizations in regulated industries face rigorous maintenance audits to ensure compliance with safety protocols and regulatory standards. When a CMMS contains bad maintenance data, the consequences can be severe.

For example, if work order history for critical equipment is incomplete or missing, auditors cannot verify that necessary inspections or repairs took place. This lack of verification can lead to costly fines, product recalls, or even shutdowns by regulatory bodies.

Additionally, poor-quality data makes it challenging to address violations promptly, as valuable maintenance resources must be dedicated to tracking down the correct information. This delay can expose organizations to additional penalties and heightened scrutiny in the future. Continued non-compliance can increase liability, damage the organization’s credibility, and undermine its ability to do business.

Learn how to pass maintenance audits

As you can see, the effects of poor-quality data are far-reaching, disrupt maintenance operations, and negatively impact maintenance efficiency.

Key performance indicators (KPIs) and maintenance reports rely on accurate CMMS data. When data is incomplete, duplicated, or incorrect, these sources of information become unreliable and mislead management decisions.

For example, missing work orders for asset failures can artificially raise Mean Time Between Failures (MTBF) calculations, making assets appear more reliable than they actually are. Duplicate records can fragment results and lead to confusing performance trends.

Similarly, work orders with incorrect start or completion times, undocumented tasks, or incomplete labor information can make Mean Time To Repair (MTTR) appear shorter than reality, while duplicated records could make it appear longer. In either case, these flawed metrics can lead to poorly informed decisions about maintenance scheduling, resource allocation, and budgeting.

Learn more about top asset management KPIs like MTBF and MTTR

When KPIs don’t match your real-world experience, it can be hard to trust your CMMS. Maintenance managers may be tempted to make decisions based on intuition rather than facts, and other business leaders may lose confidence in the maintenance team’s ability to drive reliability improvements.

Bad maintenance data comes from various sources, but a handful of factors are responsible for most CMMS data quality issues. Understanding these sources is essential for preventing poor-quality data in the first place. The following are some of the most common causes that affect CMMS data quality.

When maintenance teams are pressured to get their CMMS up and running quickly, critical steps like reviewing, cleaning, and validating data are often skipped. As a result, maintenance data is dumped into the new system “as is,” including any duplicated, outdated, or incomplete information. Once in place, it can be difficult to identify bad data and time-consuming to correct.

People make mistakes. When data is entered by hand, there is a risk of typos, skipped fields, and other data entry errors. One study found that as much as 4% of manually entered data contains errors. Other studies have found that up to 5% of data contains errors, depending on its complexity.

While this number may seem small, consider that CMMS systems contain hundreds or thousands of records, meaning that dozens of critical maintenance records may contain inaccuracies. Not only can this poor quality data lead to misinformed decisions, it also raises doubts about the reliability of other data in the system.

Standardization refers to entering data consistently based on pre-defined rules and formats. Without standardization, CMMS data may be entered in various formats, spelling, or abbreviations, which leads to further errors and confusion.

For example, one user may enter an asset number as “Pump 1,” while another user enters “Pump 001” or “P-1”. These inconsistencies make it harder to track the asset because multiple naming conventions prevent accurate search results and may cause the asset to be left out of valuable maintenance reports.

Bad maintenance data often results from poor data entry habits, especially when employees with little computing experience are expected to use a CMMS. For example, users may create new records rather than check for existing ones, skip fields when data entry seems cumbersome, or rely on memory rather than verifying information. Over time, these practices make the CMMS database cluttered, inconsistent, and harder to trust.

Sometimes, a CMMS solution’s design or lacking configuration options can lead to bad maintenance data. When essential fields are missing, users will enter information into any other available fields, even if they weren’t intended for that purpose. Systems that lack sufficient field validation allow users to enter data in non-standard formats, creating inconsistencies.

Additionally, CMMS with limited configuration options, such as mandatory fields and dropdown field customization, leave data susceptible to errors. The reliance on manual data entry without automation also significantly increases the risk of human error.

CMMS data quality can cause widespread problems, but there are effective ways to mitigate them. Ideally, bad data is caught before being entered into the CMMS. However, you can still address data quality issues after it is in the system. Consider the following strategies.

Garbage in, garbage out. Entering bad maintenance data into your CMMS will lead to poor-quality results. Therefore, organizations should clean their data before entering it into the system.

Data cleaning is the process of identifying and fixing errors within a dataset so that it is accurate and usable. This step is particularly important for organizations transferring data from a legacy CMMS, spreadsheet, or other in-house solution into a modern CMMS. Too often, organizations focus solely on migrating data into the new system without analyzing their existing data. As a result, maintenance teams struggle to derive value from the new system because they continue to work with flawed data.

For best practices on preparing maintenance data for import, check out our article Best Practices for Preparing Maintenance Data for CMMS Import.

Creating and enforcing data entry standards is vital for ensuring consistent data across the CMMS. This includes designing an asset naming convention, setting required fields, and defining appropriate data formats, such as dates or numerical values. To help users adhere to these standards, the CMMS can be configured with required fields and field validation rules. Additionally, offering users pre-selected values instead of allowing free-form entry can further minimize errors.

Resolving data quality issues is an ongoing process. Humans are prone to making mistakes from time to time, and the software can’t realistically prevent every error. Therefore, it is important that administrators regularly audit CMMS data to ensure that standards are being followed.

Schedule periodic reviews to ensure that all assets are tracked in the system, all required data is being entered, and that users are following a consistent format. Depending on the size of your dataset, consider spot checks that randomly assess a subset of records for accuracy.

Proper training ensures that technicians can effectively utilize the CMMS and maintain high data quality. Since technicians are primarily responsible for data entry, it is critical that they are well-equipped with the knowledge and skills needed to enter good data.

Training sessions should emphasize the value of accurate data by helping technicians understand how their data entry responsibilities impact maintenance operations. In addition, they should receive thorough instructions on how to navigate the CMMS and input data correctly. Vendor-provided training, user manuals, and step-by-step guides for common tasks are valuable resources for reinforcing best practices and minimizing errors.

Learn more about FTMaintenance Select training

High-quality CMMS data is the backbone of effective maintenance management. Accurate, consistent information empowers you to make strategic maintenance management decisions that minimize downtime, improve performance, and control costs. Though maintaining data quality is challenging, the costly and widespread consequences of poor data are worth avoiding. Implementing a CMMS such as FTMaintenance Select presents the perfect opportunity to establish strong data quality management practices.

FTMaintenance Select provides a centralized platform that helps you organize your maintenance data, making it easier to track, manage, and maintain data quality. By bringing together all of your critical asset, work order, inventory, and resource information in one place, you can ensure consistency across your data and reduce errors. With accurate, reliable data at your fingertips, you can make informed decisions that optimize maintenance operations. Request a demo today to learn how FTMaintenance Select can provide the insights you need for successful maintenance management.

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.75.0.0, which incorporates the following:

Features

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.74.4.0, which incorporates the following:

Solutions

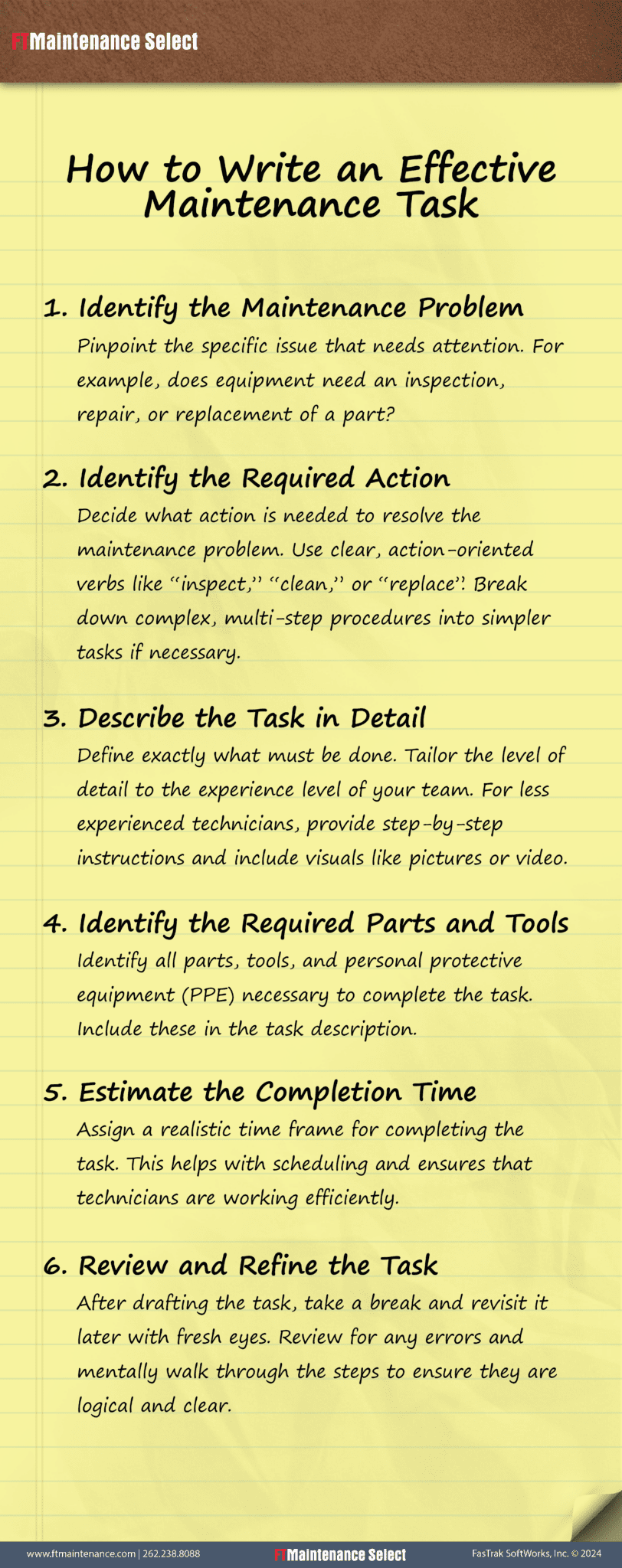

Learn more by reading our companion article How to Write an Effective Maintenance Task.

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.74.3.0, which incorporates the following:

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.74.2.0, which incorporates the following:

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.74.1.0, which incorporates the following:

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.74.0.0, which incorporates the following:

Features

Solutions

Maintenance management professionals constantly face the critical question of whether to repair or replace an asset. This decision isn’t a simple routine task; each situation presents a unique case that requires careful consideration of the costs and benefits of each option. Making this decision without thorough analysis can lead to significant financial and operational risks.

In this article, we’ll explore what to consider when making repair vs. replace decisions, walk through a typical analysis, and discuss how a computerized maintenance management system (CMMS) can help you make an informed, data-driven decision.

At its core, the goal of a repair vs. replace decision is to minimize an asset’s total cost of ownership to your organization. Rushing into a decision without proper evaluation can be costly and have other long-term effects. Each option – repair or replace – comes with its own benefits and drawbacks, which makes the decision challenging.

Repairing equipment is often a short-term, cost-effective option. Repairs are typically less expensive than purchasing new equipment, can be completed more quickly than sourcing and installing new equipment, and when done correctly, may extend the life of the asset. However, if you don’t address the underlying causes of failure, ongoing repairs will inevitably increase maintenance costs, lower productivity, and cause costly unplanned downtime.

On the other hand, replacing problematic equipment can prove to be more beneficial in the long run. New equipment typically needs less maintenance in the early stages of life, offers new features that enhance productivity, and is more reliable, but requires a significant upfront investment.

Beyond the direct costs to repair or replace, one must also consider factors including:

As you can see, balancing the costs and benefits of equipment repair versus replacement is a strategic choice requiring thorough analysis. By evaluating these factors, you can make informed asset management decisions.

Let’s conduct a basic repair vs. replace cost analysis of a forklift that experiences a transmission failure. Assume the following:

In this scenario, the forklift’s current value is relatively low, and the cost to repair is a significant portion of that remaining value. Let’s explore the business case for both the repair and replace options. To summarize, the forklift is worth $6,000 and has an estimated 3 years of useful life remaining. A transmission rebuild is quoted at $4,000 and the forklift costs $35,000 to replace.

Many sources encourage you to start your repair vs. replace analysis using depreciation, specifically straight-line depreciation, as a rule of thumb. Straight-line depreciation spreads the cost of an asset evenly over its estimated useful life.

Suppose the original forklift truck costed $30,000 and was expected to last 15 years. It depreciated in value by $2,000 every year ($30,000 ÷ 15 years = $2,000 per year). Based on this approach, the forklift’s current value is $6,000 ($30,000 original cost – (12 years × $2,000 of value lost per year) = $30,000 original cost – $24,000 depreciation = $6,000 remaining value).

While straight-line depreciation is a simple way to valuate assets, it’s primary purpose is for tax and financial reporting, as outlined by Internal Revenue Service (IRS) guidelines. These guidelines are meant to standardize how assets are depreciated for tax compliance purposes, but do not necessarily reflect actual equipment performance. As a result, accounting depreciation and the depreciation estimated by the maintenance team may not match.

Depending on the nature of a given repair, you must determine whether value will be added back to the asset in terms of performance and useful life. In this case, we must determine whether the repair will extend the forklift’s useful life.

For example, suppose you determine that rebuilding the transmission allows the forklift to fulfill its remaining 3 years of useful life. Your $4,000 in maintenance costs allows you to maintain the forklift’s operation, but does not add any new value or increase performance.

Alternatively, if you estimate that the transmission rebuild will enhance performance and extend the forklift’s useful life by an additional 3 years, the situation changes. The $4,000 repair allows the forklift to operate for another 6 years total (3 remaining useful years + 3 extended years) and you avoid the significant cost of replacement.

A common rule of thumb in repair vs. replace decisions is the “50% rule.” This guideline suggests that if a repair costs more than 50% of the cost of replacement, it is more cost-effective to replace the asset. Some organizations use a different threshold, such as the United States Marine Corps, which uses a threshold of 65%. In our example, 50% of the cost of replacement is $17,500. The repair cost is only $4,000, suggesting that repair might be a good option.

Replacing the forklift requires an upfront capital investment of $35,000, which is more than 8 times as much as the repair. However, the new forklift is expected to last for 15 years, which is an additional 9 – 12 years compared to the repaired one. Newer equipment typically has lower maintenance costs in their first few years, leading to lower maintenance costs. Additionally, any new technology, improved design, and advanced capabilities may make the new lift more productive compared to the current one.

It is important to recognize that the forklift may require other significant repairs (and as a result, downtime) as it approaches the end of its lifecycle. Future maintenance and operational costs will impact your total cost of ownership and should be factored into your repair vs. replace cost analysis.

For example, assume that the forklift’s annual maintenance cost under normal operation is $800, and costs are expected to increase by 10% each year. By the end of its 3 remaining years of useful life, you’ll incur another $2,648 in routine maintenance costs ($800 in the third-to-last year + $880 in the second-to-last year + $968 in the last year = $2,648), barring any additional major repairs. These standard repairs do not add new value to the forklift truck, and now the remaining total cost of maintenance over the 3 years is $6,648 ($4,000 + $2,648 = $6,648), compared to its current value of $6,000.

If the lifespan is extended to 6 years, the ongoing maintenance cost becomes $6,172 ($800 + $880 + $968 + $1,064 + $1,171 + $1,288 = $6,172), again barring any major repairs. Add this to the cost of the transmission rebuild, and you’re in for $10,172 ($4,000 + $6,172 = $10,172), which is about 30% of the cost to replace.

| Option | Cost | Expected Years of Service |

| Repair | $6,648 (includes repair + routine maintenance) | 3 years |

| Replace | $35,000 | 15 years, potentially more with adequate maintenance and care |

Let’s recap each scenario. Repair costs $6,648 ($4,000 repair + $2,648 ongoing maintenance costs) for an additional 3 years of service. Replacement costs $35,000, but is expected to last for 15 years with low early maintenance costs. So, is it better to repair or replace? Ultimately, the decision depends on your organization’s budget, operational priorities, and whether the long-term benefits of replacement outweigh the upfront cost. A CMMS can provide the historical maintenance data and asset performance insights needed to make this decision with confidence.

Gaining buy-in for your repair vs. replacement recommendation can be challenging without solid evidence to back you up. A CMMS provides you with the data you need to build a strong business case and justify your decision. Here’s how a CMMS can help:

The decision to repair or replace an asset directly impacts your organization’s operational efficiency and financial performance. Making these decisions without a thorough analysis can lead to costly mistakes that strain your budget and jeopardize plant productivity. A CMMS solution, like FTMaintenance Select, provides you with critical maintenance data needed to make these decisions with confidence.

FTMaintenance Select is a centralized platform for managing all aspects of your maintenance operations including work orders, equipment and facility assets, spare parts and inventory, preventive maintenance, and more. Request a demo today to learn more.

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.73.0.0, which incorporates the following:

Features

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v.3.72.0.0, which incorporates the following:

Features

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v3.70.3.0, which incorporates the following:

Solutions

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v3.70.2.0, which incorporates the following:

Solutions

Key Takeaways

Plastic products play a critical role in our daily lives, ranging from simple household items like toothbrushes and combs, to cutting-edge technology like 3D printing. With an estimated global market value of $712 billion (USD), the high demand for plastic products highlights their importance across various consumer and industrial markets.

To keep pace with current demand and expected growth, plastics manufacturers must invest in effective maintenance strategies and technologies such as computerized maintenance management system (CMMS) software. In this article, we will explore maintenance management challenges in the plastics industry and how a CMMS helps ensure efficient maintenance operations.

Maintenance management is a critical component of plastics manufacturing, ensuring that equipment remains productive and profitable. However, there are several maintenance challenges that characterize the plastics industry. The sections below discuss some of the most common.

Maintaining injection molds is challenging due to their strict durability requirements and the precision of care needed to manage them effectively. These molds can be incredibly costly, often $80,000 or more, in addition to the cost of the injection molding machines themselves. Organizations must minimize mold wear and tear through targeted maintenance while working within the constraints of the production schedule and tool and die team.

Coordination with the tool and die team adds another layer of complexity to maintenance in plastics manufacturing. The tool and die team is responsible for designing, building, and repairing the molds, and has specialized knowledge and skills critical for maintaining production quality. The overlap in responsibilities between the general maintenance team and tool and die team often leads to challenges in balancing competing priorities and coordinating access to maintenance resources.

Further, miscommunication between maintenance and the tool and die teams may influence the production team’s operations. If maintenance tasks are scheduled during critical production runs or repairs aren’t completed on time, there may be unnecessary downtime, higher maintenance costs, or quality issues.

Given the high volume of products produced in plastics manufacturing, even minor equipment issues can lead to significant quality control issues. The maintenance team plays a critical role in ensuring plastic products meet stringent requirements and customer expectations.

Equipment must be kept in good working condition to eliminate defects such as surface imperfections, warping, cracking, or other inaccuracies. This requires the maintenance team to implement process control measures that include regular calibrations, condition monitoring, and preventive maintenance, which is challenging with limited resources.

Maintaining consistent quality control also becomes difficult when investigating the origin of product defects. Conducting thorough root cause analysis (RCA) is essential, but can be complex, time-consuming, and must be balanced against other immediate needs.

Environmental conditions within the plastics manufacturing facility also pose significant maintenance challenges. The high temperatures and pressures from plastic molding and extrusion processes put considerable wear on equipment, increasing the risk of failure. Avoiding these outcomes requires tight control of asset lifecycles and maintenance practices to ensure optimal performance.

Depending on your geographic location, humidity may also play a role in equipment maintenance. Excessive moisture can be absorbed by plastic materials and result in defects. Moisture that sits on equipment surfaces can corrode molds and metal components, compromising their integrity. Maintenance teams must take measures to control the temperature and humidity levels in manufacturing spaces.

Additionally, equipment is vulnerable to damage from fine plastic particles created during production. These particulates can enter machinery, causing abrasions and damaging sensitive components. While machine operators typically handle routine cleanings, maintenance teams are responsible for disassembly and deep cleaning during scheduled downtime periods.

Just as in other manufacturing environments, the degree of communication between maintenance and production teams can present considerable challenges. Production teams expect equipment to run at peak performance and support smooth, continuous operation in order to meet production goals and deadlines. The maintenance team is often blamed if equipment fails or experiences unplanned downtime.

On the other hand, maintenance teams can struggle to gain access to equipment for repairs. Tight production schedules leave small windows open for maintenance, and any downtime can be seen as jeopardizing production quotas. This lack of access makes it difficult to perform necessary preventive maintenance, leading to the risk of more sever breakdowns and extended downtime.

Overcoming the maintenance challenges of plastics manufacturing requires a robust maintenance strategy. Computerized maintenance management system (CMMS) software provides the tools needed to meet these challenges head-on and better manage your maintenance operations. Below are some ways that a CMMS benefits the plastics industry.

A CMMS provides robust asset management features essential for tracking molds and plastic manufacturing equipment. It allows you to keep detailed records on all maintenance assets, including their specification, condition, availability, usage, and maintenance history. Using this information, you can manage asset lifecycles more effectively and ensure each piece of equipment receives the attention it needs.

In industries with high production volumes like plastics manufacturing, time is money. The consequences of downtime make reactive maintenance strategies unsustainable. The maintenance planning and scheduling features of a CMMS empower you to be more proactive about maintenance management.

CMMS software allows you to create a master preventive maintenance plan for all of your production assets, ensuring that routine maintenance is performed on time. Tasks lists allow you to define exactly what needs to be done, what materials and supplies should be used, and approximately how long routine tasks should take, leading to more consistent, quality maintenance. Work orders can then be triggered using time-based or runtime-based intervals, ensuring maintenance occurs when needed.

Some CMMS systems take proactive maintenance a step further and connect with condition-monitoring sensors. This integration supports advanced maintenance strategies like condition-based maintenance (CbM), which triggers work orders based on real-time equipment conditions, and predictive maintenance (PdM) which forecasts when equipment is expected to fail. These strategies allow you to perform maintenance only when it is needed, unlike with time-based maintenance practices.

Successful maintenance management in the plastics industry relies on effective communication and collaboration between the maintenance, tool and die, and productions teams. A CMMS ensures that the general maintenance team and tool and die team have access to the same maintenance information about production equipment and can work together to prioritize repairs and coordinate resources.

CMMS solutions also include a work request portal that allows non-maintenance employees to submit service requests directly to the maintenance team. With this feature, the production team can submit requests, check request status, and be automatically notified when requests change status or are completed. This level of transparency makes everyone aware of when maintenance will occur and creates a more collaborative relationship between maintenance and production.

Using a maintenance tracking system enables you to leverage historical maintenance data in order to diagnose why equipment failed. CMMS solutions automatically create a service history for each asset, providing you with a wealth of data that can be used to identify failure trends, track reliability following repairs, and generate maintenance management reports that reveal key insights about asset performance. This allows you to move beyond treating symptoms and address the root causes of breakdowns, thereby preventing the likelihood of the problem recurring.

Read Also: What is a Failure Code?, What is a Cause Code?, and What is a Remedy Code?

The plastics manufacturing industry faces many maintenance management challenges that significantly impact production, product quality, and overall profitability. Given the importance of plastics in our lives, organizations that fail to tackle these challenges may find it difficult to maintain consistent production.

Now is the time to modernize your maintenance operations and invest in a computerized maintenance management system (CMMS) like FTMaintenance Select. FTMaintenance Select provides robust tools for managing assets, inventory, preventive maintenance, and work requests. Leveraging this platform, you can implement proactive maintenance strategies that will reduce downtime, ensure consistent production, and set you up for long-term success. Request a demo today to learn more.

Read More about FTMainenance Select benefits for the plastics industry

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v3.67.1.0, which incorporates the following:

Features

Solutions

Learn more by reading our companion article 4 Inventory KPIs to Improve MRO Inventory Management.

Maintenance organizations face a crucial decision when choosing a computerized maintenance management system (CMMS): should the solution be hosted in-house or in the vendor’s cloud. In an era where data breaches are increasingly common, organizations are intensifying their scrutiny on data security measures. Despite the high levels of security promised by cloud service providers, many organizations are strategically choosing to host their software locally. In this article, we’ll explore why on-premise CMMS deployment remains an attractive option in today’s security-focused business environment.

On-premise CMMS deployments offer the following security benefits:

One of the primary security benefits of on-premise CMMS deployments is the full level of control it provides compared to cloud hosting. By managing your own technology infrastructure, you can tailor security measures such as firewalls, intrusion detection systems, and data encryption to meet your specific needs. This level of customization is often not possible with third-party managed cloud solutions.

Owning all the hardware and software also means that sensitive maintenance data is stored in a secure and controlled environment. This allows you to monitor systems closely and respond quickly to any potential security threats, minimizing the risk of data breaches.

Having your CMMS on-premise allows you to directly control and monitor physical access to your maintenance data. Servers and storages devices can be located in secure facilities with restricted access, round-the-clock video surveillance, adequate temperature control, and fire protection. Knowing that servers are on-site and well-protected can also increase confidence in your sensitive maintenance data’s security.

With on-premise CMMS, organizations can enforce strict access control policies to prevent unauthorized access to server rooms and data centers. Control mechanisms, such as key cards, pin numbers, or biometric scanners limit entry to servers to authorized personnel only. These controls track who entered the facility and when, making it easy to track employee activity and quickly identify any suspicious behavior.

From a CMMS perspective, access to the software requires proper licensure and authentication. Once inside the software, user access is managed by permissions and other configuration settings. This ensures that only authorized users gain access to the specific modules or functions relevant to their job responsibilities and cannot access data outside of their approved boundaries.

Being isolated from the internet significantly reduces your exposure to external cyber threats. Generally, cloud service providers have become increasingly targeted as more and more businesses have migrated to the cloud. In contrast, disconnected, on-premise solutions are much harder to access, and would likely require bad actors to breach physical security measures first.

Automatic software updates, such as those done on cloud-hosted CMMS solutions, have the potential to introduce defects, vulnerabilities, and unforeseen risks. With on-premise deployment, you have total control over when and how updates are applied, allowing time for adequate testing and CMMS software validation before rolling out updates.

Organizations that choose a locally-hosted CMMS solution benefit from the in-house expertise, which can provide custom solutions to meet your security needs. While third-party vendors have cybersecurity experts, their solutions are more generalized and may be less likely to be aligned with your unique security needs. An in-house team is intimately familiar with your infrastructure, processes, and risks, enabling them to provide a better security solution.

Certain industries may find this aspect of security the most advantageous. Industries such as government, healthcare, and pharmaceuticals, which are subject to stringent regulations and handle highly sensitive data, may require the added security and control of on-premise CMMS deployments.

In today’s world of increasing cybersecurity threats, the decision between cloud vs. on-premise CMMS deployments is becoming more important. While cloud solutions offer many benefits, growing concerns over data security are driving many organizations back to traditional, locally hosted solutions. FTMaintenance Select is one of the few solutions on the market today that offer a robust CMMS with an on-premise deployment option. Request a demo today to learn more.

FasTrak SoftWorks, Inc. is pleased to announce the release of FTMaintenance Select v3.66.1.0, which incorporates the following:

Features

Solutions

Recent Comments