| This article is part of a maintenance management metrics KPIs series. Read our other KPI articles: |

Today’s maintenance teams rely on real data – supported by hands-on experience – to effectively manage their assets. Tracking key performance indicators (KPIs) allows them to measure asset performance, evaluate maintenance strategies, and make smarter decisions about how assets are managed and maintained. In this article, we’ll cover three of the most commonly used asset management KPIs and explain how to interpret each one to continuously improve your asset management practices.

The Importance of Tracking Asset Management KPIs

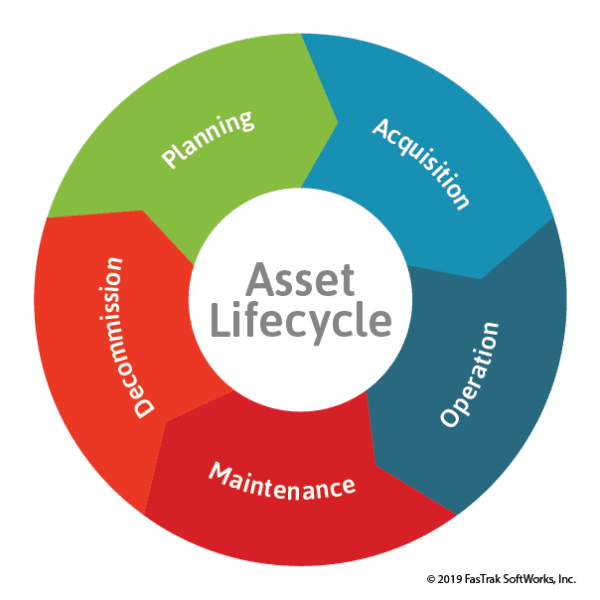

Asset management KPIs provide insight into your equipment’s reliability, availability, and overall performance. Tracking these metrics over time helps you measure your progress towards broader organizational goals, such as reducing downtime, improving safety, and lowering maintenance costs. Understanding the variables in each KPI – and what the results mean – guides your attention to what’s working well and highlights areas that may need improvement.

Top 3 Asset Management KPIs

Every organization has its own strategic business goals, which means the asset management metrics they track – and even how those KPIs are defined – can vary. Some organizations may even develop their own metrics that better reflect their industry, regulatory environment, or internal processes.

That said, there are three core asset management KPIs widely used across industries: Mean Time to Repair (MTTR), Mean Time Between Failures (MTBF), and Overall Equipment Effectiveness (OEE). These metrics provide a foundation for evaluating asset performance and identifying areas for improvement.

Mean Time to Repair

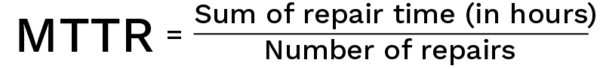

Mean Time to Repair (MTTR) is the average time it takes to restore an asset to working condition– from when the technician begins work until the asset is returned to normal operation. It is calculated by dividing the total time spent on corrective maintenance by the total number of repairs.

Repair time includes only the time spent performing the repair itself, also called “wrench time”. It does not include time spent waiting for access to the equipment, parts, technician availability, work approvals, or other maintenance processes. The calculation assumes that all necessary resources are available.

To be most useful, MTTR should be calculated per asset and per type of failure, since different failure types involved different levels of expertise, troubleshooting, time, and effort to resolve. Therefore, failures with vastly different repair times should not be grouped together when calculating MTTR.

MTTR Example

Over the course of six months, a motor had to be repaired 4 times due to a bearing failure. Technicians spent a total of 12 hours repairing the motor.

MTTR = 12 repair hours ÷ 4 repairs = 3 hours

On average, it takes 3 hours to repair the motor following a bearing failure.

How to Interpret Mean Time to Repair

MTTR helps maintenance teams evaluate how quickly they can resolve unplanned failures, and is used to predict how long a particular piece of equipment will be unavailable depending on the nature of the failure.

A low MTTR means that technicians can carry out repairs quickly. It typically reflects that technicians are knowledgeable and well-trained and that work instructions are clear. Low MTTR across similar failures also indicates that those tasks are relatively simple and do not take much time to complete.

For example, replacing a blown fuse might take just 10-15 minutes, while replacing a gearbox could take several hours. If you were to average both types of failures together, your MTTR would overestimate the time needed to replace a fuse, and greatly underestimate the time required for a gearbox replacement. That’s why it’s important to calculate MTTR by failure type.

A high MTTR can indicate that repairs are complex, equipment is difficult to maintain, or that technicians cannot complete the work in a timely manner. As assets age, they become more difficult to repair. Calculating MTTR can show how long certain repairs take compared to similar assets and help you build a business case for replacement.

Workforce and management issues may also lead to undesirable MTTR calculations. Technicians may lack the proper skills or training, or work instructions may be vague, requiring technicians to spend extra time interpreting what needs to be done. Calculating MTTR by labor resource – in addition to by asset and failure type – can help reveal whether issues lie with your workers or somewhere else.

In some cases, a consistently high MTTR may suggest a need for increased or adjusted preventive maintenance. If certain failures take significant time to repair, more frequent inspections or other targeted tasks could help reduce the likelihood or severity of those failures and lower MTTR over time.

Read Further: How to Measure Preventive Maintenance Effectiveness

While MTTR focuses on how quickly assets can be returned to service, it’s most meaningful when paired with metrics like Mean Time Between Failures (MTBF). Tracking both helps maintenance teams understand whether they’re putting out fires or responding to rare, unavoidable issues.

Mean Time Between Failure

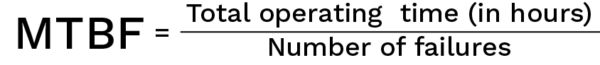

Mean Time Between Failures (MTBF) is a measure of an asset’s reliability – specifically, how long equipment performs its intended function under normal operating conditions before a failure occurs. MTBF directly affects availability – the amount of time equipment is operable – and can be used to evaluate the effectiveness of maintenance strategies, track asset health, and set reasonable expectations for the timing of future failures.

MTBF is calculated by dividing the total operating time (the time equipment is functioning as intended) by the number of failures within a given time period.

In this context, operating time is the period of time when the asset is functioning as intended. It excludes time spent offline due to failures, scheduled maintenance, or planned downtime. Like MTTR, MTBF is most useful when calculated per asset and failure type, since different failures tend to occur at varying frequencies.

MTBF Example

Suppose the same motor from our earlier example ran for 2,000 hours in the six month period. The bearing failure occurred 4 times. Therefore:

MTBF = 2,000 hours ÷ 4 failures = 500 hours

This means the motor operates, on average, for 500 hours between bearing failures. However, keep in mind that this is just an estimate. A bearing failure may occur well-before or well-after the 500 hour mark. As you collect more data, this calculation will become more accurate and lead to more predictable maintenance needs.

How to Interpret Mean Time Between Failures

Tracking MTBF helps organizations monitor asset performance over time and make informed decisions about asset reliability.

A low MTBF value indicates frequent failures, and may suggest that equipment is nearing the end of its useful life, but that is not always the case. Frequent failures may also be caused by poor maintenance, incorrect operation, or ineffective preventive maintenance.

When MTBF is consistently low, maintenance teams should look at several potential factors before considering replacement:

- Preventive Maintenance Plans: Are the right tasks in place to prevent specific, frequent failure types?

- Maintenance Quality: Are technicians treating symptoms rather than performing proper troubleshooting? Are technicians rushing work? Is the asset a candidate for further root cause analysis?

- Operating Conditions: Is the asset being used according to manufacturer specifications? Are misuse or environmental factors reducing reliability?

- Training: Are operators and maintenance technicians properly trained? Are standard procedures being followed?

If equipment continues to fail despite addressing these areas, MTBF measurements provide objective data to support repair vs. replacement decisions.

A high MTBF value, on the other hand, means that equipment is operating reliably, well-maintained, and properly used, suggesting that your current maintenance strategy is working. However, it is important to regularly measure MTBF to check for early signs of wear and be aware of other potential issues before failures occur.

When used in conjunction with MTTR, MTBF paints a fuller picture of asset performance. MTBF tells you how often failures happen, while MTTR tells you how long those failures stop operations. Together, these asset performance metrics help assess both the frequency and impact of unplanned downtime.

Overall Equipment Effectiveness

Overall Equipment Effectiveness (OEE) measures the productivity of an asset over a period of time. It is expressed as a percentage from 1% to 100%, with the higher the percentage indicating better performance.

This KPI is typically used in manufacturing environments that practice lean manufacturing. While the maintenance team may not be responsible for tracking this KPI, it is important to understand how maintenance activities contribute to reaching OEE targets.

This KPI is more complex than MTTR or MTBF, but it can be broken down into three simple components. To calculate OEE, multiply the equipment’s availability, performance, and quality together.

![]()

- Availability: how often equipment is ready when scheduled

- Performance: how fast equipment operates vs. its maximum speed

- Quality: how many units produced meet quality standards

For a deeper dive into OEE, read our article What is Overall Equipment Effectiveness?

OEE Example

A piece of production equipment has 87% availability, 95% performance, and 93% quality. Therefore:

OEE = 0.87 × 0.95 × 0.93 = 0.7686 = 76.86%

How to Interpret Overall Equipment Effectiveness

Overall Equipment Effectiveness helps manufacturers identify where inefficiencies might exist in their production process. It gives insight into whether your equipment is available when it should be, producing at its expected rate, and making quality parts. Maintenance activities often contribute to each of these factors.

Low availability means excessive unplanned downtime, which may be caused by poor reliability, slow repairs, or ineffective preventive maintenance. Tracking Mean Time to Repair (MTTR) can help you uncover what’s holding back repairs from being completed quickly. Similarly, tracking Mean Time Between Failures (MTBF) can help determine why equipment is failing frequently.

Low performance means that machinery is running slower than expected, which may be due to wear and tear, improper calibration, or operator issues. Maintenance teams can help diagnose, analyze, and address many of these issues.

Low quality may stem from equipment running outside of specification, indicating a need for additional preventive maintenance inspections and adjustments.

The higher OEE, the better; however, keep in mind that there are limits to how high an OEE is realistically possible. LeanProduction.com offers the following OEE benchmarks:

- Perfect (100%): Perfect production – manufacturing only good parts, as fast as possible, with no stop time.

- World Class (85%): Considered world class for discrete manufacturers.

- Typical (60%): Typical for discrete manufacturers, but leaves room for improvement.

- Low (40%): Common for manufacturers just starting to track and improve production performance. Can be easily improved.

Tools for Tracking Asset Management KPIs

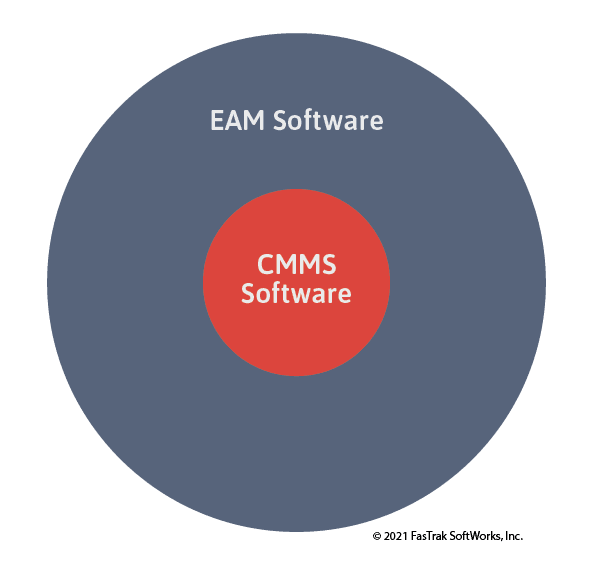

Tracking asset management metrics like MTTR, MTBF, and OEE requires access to reliable, accurate, and up-to-date maintenance data. Computerized maintenance management system (CMMS) software provides just that.

A CMMS tracks and stores key maintenance data such as wrench time, failure records, and service history, which form the basis of KPI calculations. With all of this information stored in one place, you can create dashboard visualizations and reports that help measure progress towards your goals over time.

Improve Asset Performance with FTMaintenance Select

FTMaintenance Select is a powerful asset management platform that captures and connects critical maintenance data to help you achieve your strategic goals. By centralizing asset information alongside service requests, inventory, work orders, and more, FTMaintenance Select enables you to effectively monitor asset health, reduce downtime, and improve performance. Request a demo today to see how FTMaintenance Select supports smarter, data-driven asset management.

Recent Comments