In modern maintenance environments, nothing happens without a plan. Behind every inspection, repair, or replacement lies formal documentation of what’s to be done. More than just a piece of paper, maintenance work orders are the starting point for effective maintenance. In this article, we’ll explore what a maintenance work order is and why it is critical to successful maintenance operations.

What is a Maintenance Work Order?

A maintenance work order is a formal document that describes a maintenance task and authorizes the maintenance team to perform the work. Sometimes referred to as “jobs,” maintenance work orders outline activities such as routine inspections, part replacement, and repairs. Typically, they specify what work is required, who is responsible, when it’s due, and how to complete it.

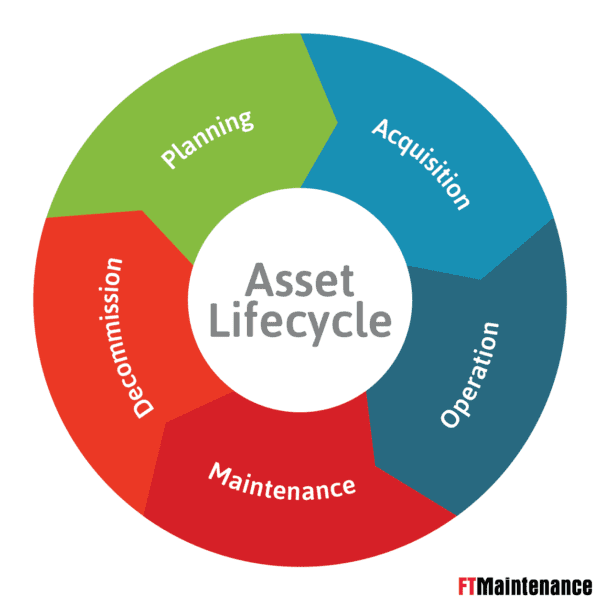

A maintenance work order is a “living” document that serves many purposes throughout its lifecycle:

- At creation, it provides a clear description of the work to be performed.

- During execution, it tracks progress and notes any changes or issues.

- At completion, it summarizes the work that was done and verifies that it was performed as intended.

- During analysis, it becomes a historical record that provides insights into recurring maintenance issues, team productivity, and asset performance.

Types of Work Orders

There are multiple types of maintenance work orders. Depending on the organization, they generally fall into one of the following categories:

- Corrective Maintenance (CM): Issued to restore assets to optimal or operational condition after a failure or issue is identified.

- Preventive Maintenance (PM): Scheduled in advance for time-based or usage-based tasks such as inspections, cleaning, or part replacements.

- Condition-based Maintenance (CbM): Generated in response to real-time equipment data from condition-monitoring sensors, triggered when performance falls outside of acceptable thresholds.

- Predictive Maintenance (PdM): Triggered proactively based on asset service history, real-time condition data, and predictive analysis to anticipate failures before they occur.

Who Creates Maintenance Work Orders?

While most work orders originate from within the maintenance team, they can be created by a variety of people, depending on your organization’s structure and type of maintenance being performed. Below are some common sources of maintenance work orders:

Requesters

Non-maintenance personnel – such as employees, operators, customers, or tenants – may report issues through a maintenance request system. These requests are typically reviewed and converted into work orders by the maintenance team.

Maintenance Managers

Maintenance managers, or other employees in a maintenance planning role, often create work orders to schedule planned maintenance or respond to reported issues.

Maintenance Technicians

Technicians may create work orders in response to problems noticed during preventive maintenance inspections or other tasks. It’s also common for technicians to create work orders after the fact, especially when responding to breakdowns or emergencies.

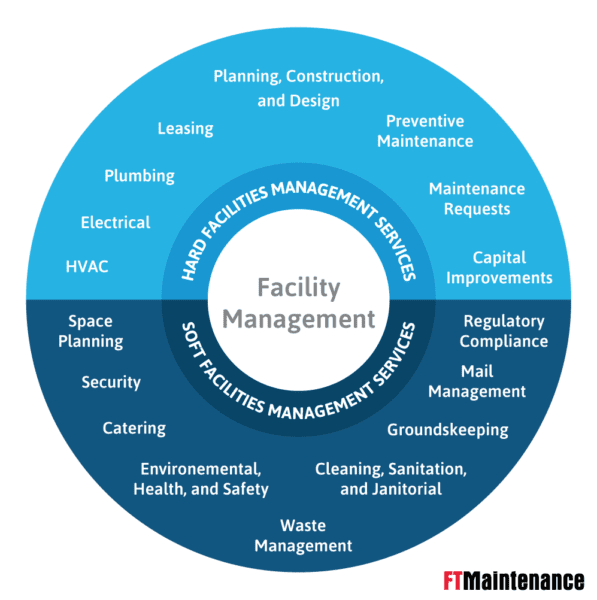

Department Leaders

Leaders of departments that depend on the maintenance team, such as production, facility management, and operations, may submit requests or create work orders directly, depending on their access to the work order management system.

Work Order Software

Work order software, like a computerized maintenance management system (CMMS), can automatically generate work orders for recurring tasks using time-based or usage-based triggers. In more advanced organizations, CMMS software may be integrated with sensors or control systems that trigger work orders based on real-time equipment data. In addition, mobile CMMS software allows technicians to create work orders from the field or job site.

Learn more: What is a CMMS?

Lifecycle of a Maintenance Work Order

A maintenance work order goes through multiple stages throughout its lifecycle:

- Inception: Maintenance work is identified through a maintenance request or a work order template for planned maintenance.

- Creation: A maintenance work order is generated, containing details about the task. The work order is prioritized, scheduled, and assigned according to an organization’s work order management process.

- Performance: Technicians perform the tasks per the work order and document the resources used to complete it.

- Closure: Following completion of the work, the maintenance work order is filed away and becomes a permanent record of what was done and what resources were used.

- Analysis: Closed work orders are used to troubleshoot asset breakdowns, reviewed to identify failure trends, patterns, and track work order management KPIs.

While this lifecycle represents a typical work order process, each organization may manage their work orders differently based on their tools, procedures, and goals. To visualize this process, download our Work Order Management Process infographic.

What to Include in a Maintenance Work Order

The information included on a maintenance work order depends on your organization’s needs. Below are the most common fields included on a maintenance work order during its creation. Remember, technicians may add additional details and documentation as they carry out their work.

- Work Order Number: A unique identifier used to track the work order.

- Requester Information: The name and contact details of the requester, tenant, or customer.

- Asset Information: The name and ID of the asset or equipment requiring maintenance.

- Location: The physical location of the asset or place where maintenance will be performed.

- Problem Description: A clear description of the scope of work to be completed.

- Instructions: The specific tasks or procedures the technician must follow, most commonly used for preventive maintenance activities.

- Parts and Materials: A list of parts, supplies, and materials, along with their quantities.

- Tools Required: Any special tools or equipment needed to complete the job.

- Assignee: The technician or team responsible for completing the work.

- Time Estimate: How long the work order is expected to take.

- Deadline or Schedule: The desired or required completion date.

- Cost Estimate: An estimate of the labor, parts, tools, and other costs. For service providers, this may reflect the cost billed to the customer.

- Attachments: Supplemental information such as images, videos, or other maintenance documentation.

The fields here are focused on the work itself, and do not include other information such as priority, labor craft, maintenance type, or risk level. While optional, including this additional context helps determine who is qualified to perform the work, how urgent the task is, and what resources may be needed.

How to Manage Maintenance Work Orders

Many organizations use manual, paper-based or spreadsheet-based methods for managing maintenance work orders. While these systems are familiar “tools of the trade” to many teams, they lack the interconnectivity and automation of modern work order software.

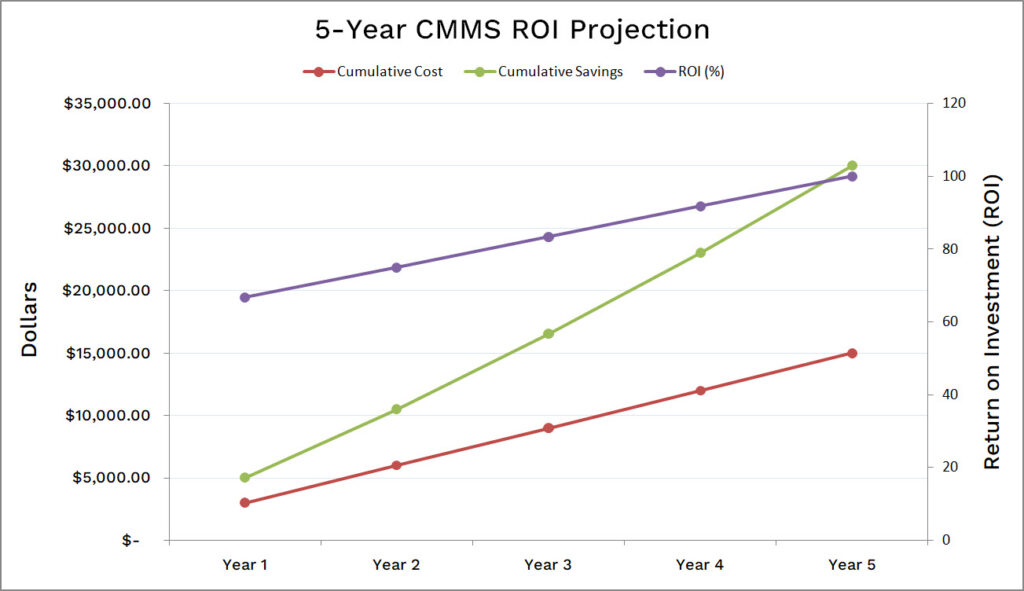

Work order management is a core function of computerized maintenance management system (CMMS) software. A CMMS helps organizations create, manage, track, and analyze maintenance work orders. The main advantage of a CMMS over other systems is that it connects maintenance work orders with other key maintenance data within a single system. This integration provides greater visibility into maintenance operations, making work order management more efficient while supporting better decision-making across the maintenance process.

To learn more about how a CMMS supports work order management, read our article What is Work Order Management?

Track Maintenance Work Orders with FTMaintenance Select

Maintenance work orders are crucial to successful maintenance operations, as they help track work from start to completion. FTMaintenance Select CMMS is work order software that helps organizations generate, manage, and track work orders within a centralized system.

Whether you’re scheduling preventive maintenance or responding to urgent repairs, FTMaintenance Select gives you the tools to stay organized and in control of your work order management process. Request a demo of FTMaintenance Select to discover how digitized work orders can transform your maintenance operations.

Recent Comments