In many organizations, the word “audit” evokes feelings of annoyance, anxiety, and fear. In reality, audits are not as bad as they are made out to be. By understanding how maintenance audits work, you will see why maintenance audits are nothing to fear, especially if you are using computerized maintenance management system (CMMS) software.

In many organizations, the word “audit” evokes feelings of annoyance, anxiety, and fear. In reality, audits are not as bad as they are made out to be. By understanding how maintenance audits work, you will see why maintenance audits are nothing to fear, especially if you are using computerized maintenance management system (CMMS) software.

What is a Maintenance Audit?

A maintenance audit is a systematic, comprehensive review of an organization’s maintenance processes and/or systems. It evaluates how well maintenance activities and their related results conform to set standards. Through a review of objective evidence, auditors determine whether maintenance procedures meet requirements, are effectively implemented, and are appropriate to reach desired outcomes.

Maintenance audits are usually conducted as a part of quality or health and safety audits. Quality audits verify an organization’s compliance to industry standard specifications or procedures. Health and safety audits determine whether a product is safe and whether the maintenance process has kept products from being contaminated or damaged.

The Importance of Maintenance Audits

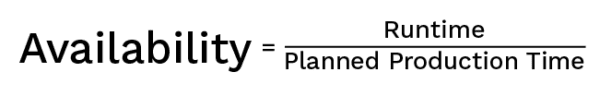

Maintenance audits are an effective business tool. First, they provide a true picture of plant activities that allow the organization to set benchmarks for operations. This baseline data is compared to what should be done. If differences exist, the organization can implement solutions to address them.

Audits also protect an organization from liability. They are an integral part of a well-designed system to ensure end products are safe for consumers. Regulatory and compliance audits compare processes to industry standards. Safety audits help organizations reduce the risk of workplace injuries and health hazards.

A third reason maintenance audits matter is because they hold organizations accountable. Audits are usually conducted by third parties who understand the business or industry standards, and bring an outsider’s perspective to an organization’s operations. Their unbiased, objective approach ensures the integrity of the results.

Types of Maintenance Audits

There are several types of maintenance audits: mandatory, voluntary, and internal. Mandatory audits are required by law and carried out by governmental agencies that oversee an industry. Maintenance processes may be reviewed as a part of these audits. For example, the U.S. Food and Drug Administration audits the pharmaceuticals industry to ensure compliance with manufacturing processes according to their Current Good Manufacturing Practices (CGMP), Title 21 Parts 110, 111, and 211.

Voluntary audits are used to obtain certification that provides an organization with a competitive advantage. The International Organization for Standardization (ISO) 9001 certification, for example, demonstrates an organization’s commitment to being best in class and providing high quality products and services. Though this certification is voluntary, some organizations require that their business partners also attain certification. Safe Quality Foods (SQF) certification in the food and beverage industry is another example.

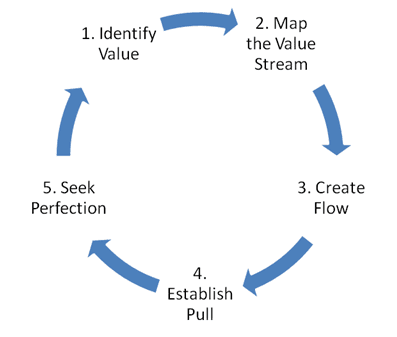

A third type of maintenance audit is an internal audit that is part of a continuous improvement plan. Organizations perform regular internal audits to ensure that their maintenance processes remain effective as maintenance operations change over time. Results of these audits are compared against internal company codes and policies, requirements of contractual commitments, and other key performance indicators.

What Happens During a Maintenance Audit?

No matter what format the audit takes, auditors check how well your standard operating procedures (SOPs) adhere to established best practices. They look for evidence that you: 1) say what you do, 2) do what you say, and 3) can prove it. Auditors verify your compliance through fieldwork in the form of observation of maintenance processes, employee interviews, and a review of the documentation system or CMMS.

What Do Auditors Examine?

Maintenance audits cover a wide swath of maintenance functions. According to Manufacturing.net, maintenance audits are broken down into several categories:

-

- Maintenance organization

- Maintenance practices

- Equipment maintenance

- Safety

- Planning and scheduling

- 5S

- Cooperative maintenance

- Training

- Document management

- Maintenance inventory and purchasing

How Often Do Audits Occur?

Whether an organization is audited at all depends on the industry in which the organization operates. Generally, most maintenance audits are conducted in manufacturing or regulated maintenance services, such as airline maintenance. The frequency of audits depends on the auditing agency.

Audits may be scheduled or come as a surprise. For example, the FDA performs both announced and surprise audits. Audits may become more frequent if there have been past shortcomings or failures. Internal audits are conducted at the discretion of the organization and their quality team. In extreme circumstances, audits may be called for as part of an investigation following workplace injuries or when products cause unintentional harm to consumers.

How to Pass a Maintenance Audit

Maintenance audits aren’t something to fear. After all, millions of companies pass audits every year, so there is no reason to stress. Organizations that use a CMMS find that much of what auditors want is readily available.

Furthermore, maintenance audits are actually a good thing. They ensure that the organization is providing safe and effective products and services. Complying with regulations or achieving a certification informs the public that the organization is committed to high-quality standards. Ultimately, these benefits make your organization’s products more attractive and profitable.

Follow the steps below to make your next audit quick and painless.

Read more about how a CMMS prepares you for compliance audits

1. Implement a CMMS

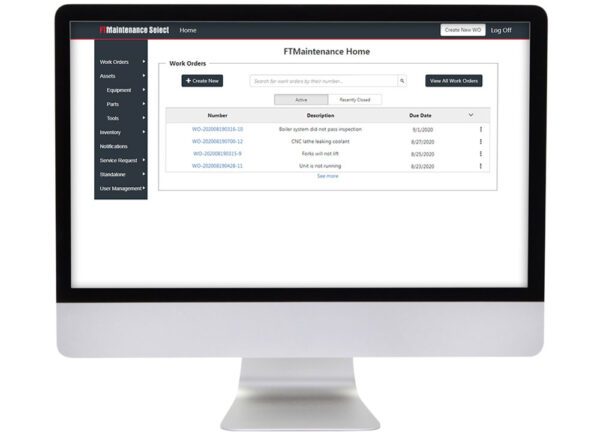

Having a CMMS is a huge advantage when it comes to providing the documentation required by audits. The most important piece of documentation is the work order which tracks maintenance activities from start to finish.

During creation, standard operating procedures are communicated to technicians in the form of tasks. The work order’s task list provides step-by-step instructions for completing the job. When work is executed, technicians can mark tasks as complete, as well as document other information such as how much time was spent and what parts were used. Closed work orders create a history that shows work was completed according to the assigned procedure.

If you do not currently own a CMMS, now is the time to consider getting one. You will need time to identify and purchase a system, train users, and integrate the CMMS into daily maintenance operations. We have created a definitive guide that walks you through the process of CMMS acquisition and implementation.

2. Prepare Your CMMS

Your CMMS must demonstrate and reinforce your maintenance process. In preparation for an audit, make sure that procedures are up-to-date and inclusive of all operations, such as lockout-tagouts and any procedure that proves compliance with quality or health and safety issues.

Further, check that all maintenance work is documented in the system. Basically, if it isn’t documented, it didn’t happen. This includes updating work orders with all tasks that have been performed and marking those tasks as complete.

Some systems include features that automatically track user activity, providing further proof of what was done and who did it. If your organization uses a work order approval process, make sure it is recorded and that employees can find that documentation.

3. Prepare Your Team

As mentioned earlier, maintenance audits involve interviews with employees to make sure that they know how to do their jobs. Therefore, you must prep your team for these interactions.

Coach your team to answer auditors carefully and have them refer to SOPs if needed. This can be as easy as instructing technicians to say, “I do what the work order tells me.” If the auditor requires proof that procedures have been followed, technicians can simply pull up the work order history in the CMMS.

Auditors also verify that employees are properly trained. Expect auditors to ask employees to demonstrate how they use the CMMS to view asset records, access maintenance documentation, and complete work orders.

4. Tidy Up

Audit preparation is the perfect time to make sure everything is in order. That includes ensuring the physical facility is clean, organized, and presentable.

Areas used by the maintenance team, such as offices, repair areas, and inventory storage locations should be neat and well organized. Facilities should be reasonably clean and free of clutter. Address any other safety or housekeeping issues as well.

Fear Not!

By now, you can see why maintenance audits are nothing to fear. Let’s return to an auditor’s criteria to see how a CMMS fits in:

- Say what you do: Document your standard operating procedures and other maintenance policies in the CMMS.

- Do what you say: Train users how to use the CMMS effectively. Ensure that users check off their tasks and record their work. Remember, if it isn’t documented, it didn’t happen.

- Prove it: Close work orders to create a maintenance history.

When it comes down to it, organizations that consistently use a CMMS have an easier time passing maintenance audits.

Prepare for Your Next Audit with FTMaintenance

FTMaintenance is a CMMS that provides a single platform for documenting, tracking, and managing maintenance activities. It allows you to digitally track information about your assets, MRO inventory, work orders, and labor resources in a centralized location. When audits occur, information stored in FTMaintenance is readily available. Request a demo today to see how FTMaintenance can help you pass your next maintenance audit.

Recent Comments